Wall studs 10 vs pine framing MGP10 and MGP12

On live projects, wall studs decide whether walls stay straight or fight every trade on site. Builders know this from long experience. They still rely on pine framing for much of the skeleton, yet they now feel new pressure from tall walls, wide openings, and demanding finishes. Frames must stand true for tiles, cabinets, and large windows, not just plasterboard. That is where engineered options step forward.

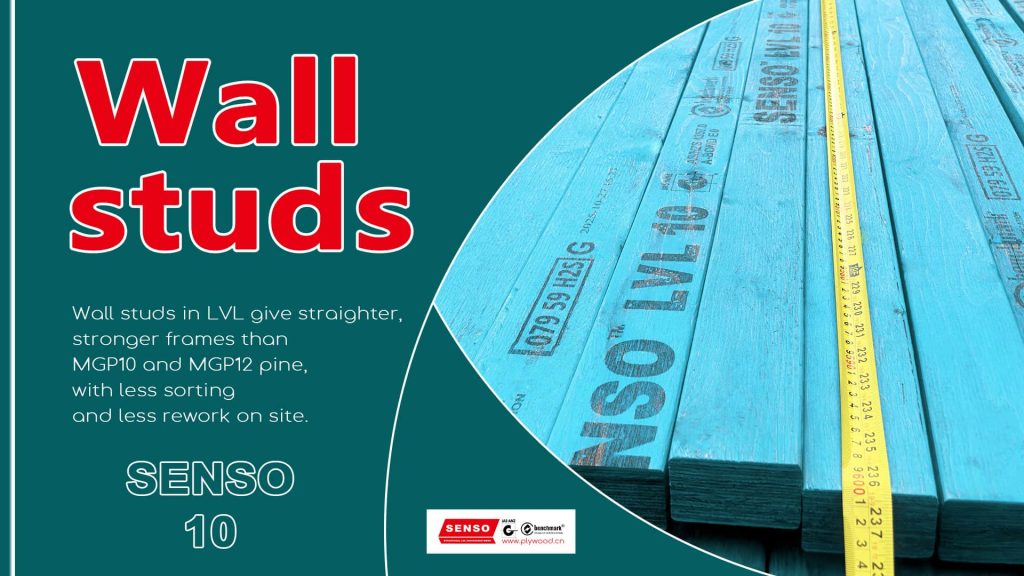

SENSO Wall studs 10 grew from this shift. We looked at common framing issues and asked a simple question. How do we keep the practical feel of timber framing, while giving crews straighter and more stable studs? The answer uses laminated veneer lumber as the base. Our wall studs fit standard layouts, yet they bring a different level of consistency compared with many packs of MGP10 timber or MGP12 pine.

Why Wall stud quality now matters more than ever

Homes and light commercial buildings keep changing. Ceiling heights rise, spans increase, and clients expect sharp lines everywhere. A slight bow in a stud once hid behind simple linings. Today it may run behind full height tiles, stone splashbacks, or high gloss cabinet banks. Small twists in wall studs now create visible issues that cost time and money.

At the same time, labour remains tight. Many framing crews carry apprentices or short term staff. Teams cannot afford long hours spent sorting twisted boards or straightening walls by hand. They want packs that give high yield, predictable behaviour, and a smooth fix. As a result, attention moves from only price per metre to the total impact of each stud on the build.

For wholesalers, this change appears in new questions. Customers ask more about stability, straightness, and long term performance. They still want sharp pricing, yet they also seek products that lower risk on high value jobs. When we discuss SENSO Wall studs 10 with partners, we focus on these practical themes, not just design numbers.

How LVL timber differs from pine framing

Pine framing begins with solid boards sawn from logs. Graders test stiffness and assign grades such as MGP 10 timber or MGP 12 pine. These grades work well and follow long standing rules. However, each board still reflects the grain and growth of a single tree. When moisture changes, that natural structure can move. Bowing, twisting, or cupping may appear as boards dry on site.

LVL timber starts from a different idea. Thin veneers run along the length of the member. We bond them under heat and pressure with structural glue. This build spreads natural defects and evens out variation. The result is an engineered product with stable strength and stiffness values along its length. Laminated veneer lumber also responds to moisture change in a more predictable way.

For wall studs, that difference feels clear. Packs of SENSO Wall studs 10 arrive with a very high proportion of straight, usable pieces. Crews can pull, cut, and fix without long sorting runs. Pine framing still plays a key role in simple walls and partitions. Yet the LVL option offers a stronger tool when project demands keep rising.

To highlight the contrast, the table below compares basic behaviour across common stud choices.

| Property | LVL wall stud (SENSO Wall stud 10) | MGP10 timber | MGP12 pine |

| Source material | LVL timber, multiple veneers | Solid softwood board | Solid softwood board |

| Strength variation | Low, engineered control | Higher, depends on each board | Moderate, better than MGP10 |

| Straightness in the pack | Very consistent | Varies by pack and supplier | More consistent, still variable |

| Movement with moisture | Controlled, lower than many solids | Noticeable movement | Similar to MGP10, sometimes less |

| Ideal use | Tall, tiled, high value walls | Simple internal walls | Taller walls where LVL not adopted |

SENSO Wall stud 10 in real site conditions

Design tables give numbers, yet performance on a wet, busy site tells the true story. SENSO Wall studs 10 handle real onsite change very well. We dry veneers to tight limits before pressing. We then press and condition members to balance moisture through the section. That care helps limit unexpected shifts when frames stand open to rain and sun.

On the frame, carpenters notice the difference in several ways. Stud lines stay straight between plates. Corners build square with less force. Tall walls feel firm under hand pressure, even before linings go on. When sheeting starts, fixers see nail lines fall more consistently down stud centres. These small gains add up across a floor or entire townhouse row.

Compared with pine framing, the mood on site often feels calmer. Crews still use familiar tools and fixings. They still work within normal timber framing methods. They just handle studs that behave in a more reliable way. That reliability becomes even more valuable when project timelines tighten or a storm front rolls over an open frame.

Comparing Wall studs 10 with MGP10 timber and MGP12 pine

When buyers compare studs, they usually weigh three things. They look at strength, stiffness, and how studs behave during and after construction. Price per metre stays important, yet they now link it more closely with labour and rework. In this view, each choice holds a clear position.

MGP10 timber sits as the entry level framing grade. It supports many low rise homes and simple partitions. Its price stays attractive, yet it brings higher movement and more variation. MGP 12 pine improves strength and stiffness. It suits taller walls and higher loads, yet still follows the limits of natural solid boards.

SENSO Wall studs 10 bring LVL timber into this line up. They offer high stiffness and stable strength along the length. That extra stiffness reduces deflection in tall walls and around large openings. Tilers, plasterers, and cabinet installers benefit from flatter surfaces. The frame stays closer to the designer’s intent long after handover.

The comparison below sets these points side by side.

| Factor | SENSO Wall studs 10 | MGP10 timber | MGP12 pine |

| Base material | Laminated veneer lumber | Solid pine | Solid pine |

| Typical stiffness level | High, suits tall or loaded walls | Moderate | Higher than MGP10 |

| Sorting time on site | Short, high usable yield | Longer, more rejects | Moderate |

| Suitability for tall walls | Very strong choice | Needs careful design | Good, with movement control |

| Finish quality support | Excellent for tiles and cabinets | Adequate for simple finishes | Good, still depends on board choice |

Cost view for Wall stud and pine framing

Material price per metre is easy to measure. Total cost per project is harder, yet more important. LVL wall studs often carry a higher unit price than comparable MGP10 timber and sometimes more than MGP12 pine. On a simple spreadsheet, that difference stands out. On a real project, the picture changes once labour and rework enter the calculation.

Frames built with a high share of straight, stable studs need less adjustment. Crews can frame faster and spend more time on planned tasks rather than rescue work. Fixers, tilers, and cabinet installers also move quicker in rooms where walls line up. Every hour saved helps offset the premium for engineered studs. Callbacks then sit as the final element. If one return visit disappears because a wall stayed straight, that saving may equal a large bundle of studs.

The table below gives a simple cost lens. It does not show exact dollars, because markets differ, yet it helps guide thinking.

| Cost factor | LVL wall stud (SENSO Wall stud 10) | Pine framing (MGP10 / MGP12) |

| Price per metre | Higher | Lower |

| Labour during framing | Lower, smoother workflow | Higher from sorting and straightening |

| Risk of rework | Reduced, especially in key rooms | Higher in tall or tiled walls |

| Likelihood of callbacks | Lower where used in critical zones | Higher where walls move over time |

| Overall value in complex builds | Strong | Depends on design and finish level |

Design and durability with structural LVL beams

Wall studs never work alone. Loads flow through plates into beams, lintels, and floors. Many engineers now use structural LVL beams for long spans and concentrated loads. Pairing those beams with LVL wall studs creates a more even, predictable system. The stiffness of the wall better matches the stiffness of the beams above.

This match helps in several ways. Openings stay square under load. Tall walls carry point loads without local crushing or bending. Raking ceilings find strong support at rafter feet. When LVL timber appears in both beams and studs, design values align in a clear, consistent way. Engineers gain flexibility with bracing layouts and can sometimes reduce over sized solid sections.

Durability also matters here. Structural LVL beams, combined with LVL wall studs, handle moisture swings with more stability than many solid boards of similar size. Treatment options then address termites and decay risk. As a result, the frame holds its shape better through the wet build period and into service life. That outcome supports longer term performance in real climates, not just in controlled tests.

Where Wall studs 10 add the most value

No builder needs LVL in every single stud. A smarter approach uses each product where it makes the most sense. SENSO Wall studs 10 show the strongest value in high risk or high value areas. Bathrooms with full height tiles sit at the top of that list. Here, movement behind finishes can crack grout, break sealant lines, and cause water problems. Stiffer, more stable studs sharply lower that risk.

Kitchens and laundries follow. Heavy cabinets, tall splashbacks, and integrated appliances prefer walls that carry loads without bending. Engineered wall studs support these points and keep lines tight around doors and panels. Feature walls in living areas also benefit. Tall entries, raking ceilings, and wide glazing all depend on firm stud lines. LVL wall studs reduce the chance of bowing that could spoil sight lines.

For simple internal partitions and short bedroom walls, pine framing still offers a fair answer. MGP10 timber or MGP12 pine can handle basic loads at low cost. Many builders therefore adopt a mixed framing map. They draw zones where SENSO Wall studs 10 become standard and keep pine framing for less demanding stretches. This layered system protects budgets while lifting performance where it matters most.

Practical guidance for wholesalers and builders

Wholesalers hold a key role in this shift. By stocking SENSO Wall studs 10 alongside conventional pine framing, they give customers a clear upgrade path. Sales teams can talk with builders about specific rooms and risk points. They can then help design a simple plan that uses LVL wall studs in those spots. This style of support turns a material sale into a joint framing solution.

Builders, in turn, gain a way to step forward without upsetting their current methods. They keep existing tools, plates, and fixings. They adjust only the stud choice in agreed walls. Over a few projects, site teams see frames grow more predictable. Supervisors then choose whether to expand LVL use or keep the mixed model. Either way, knowledge grows and partners refine the balance between cost and performance.

SENSO backs this path with stable supply, clear data, and field support. Our experience in LVL timber, wood beam products, and structural LVL beams feeds into every pack of SENSO Wall studs 10. For wholesalers and construction companies, that depth means less guesswork and more confidence on each order. As wall studs take on more responsibility in modern designs, that confidence becomes one of the most valuable parts of the frame.

SENSO LVL 10

SENSO LVL 10 for fast, accurate framing. The product suits tall walls and wide openings. Each piece is stable and straight. Moisture control helps jobs in changeable weather. Termite treatment protects homes in risk zones. Edges are clean for fast fixing. LVL studs keep layouts true during sheathing. LVL studs also reduce site waste and rework. The range matches common wall stud framing sizes. Supply is steady for large projects.

Post time: Dec-10-2025