Wall stud LVL 10 vs pine framing

Choosing the right framing system feels simple on paper, yet it shapes the whole job. Material choice influences wall line, fit-out speed, waste volume and even how owners judge the home years later. Today, the real decision often sits between an LVL 10 Wall stud and familiar MGP10 and MGP12 pine framing.

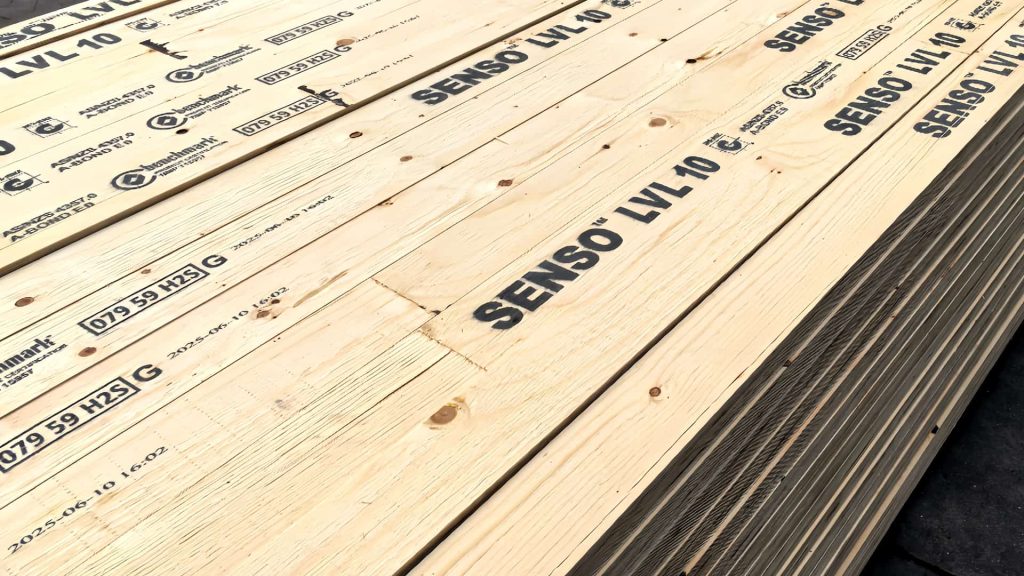

All three options meet typical code needs when sized and spaced correctly. However, they behave very differently on site. The differences show up when walls stand, linings go on and cabinets, tiles and doors meet the frame. As a manufacturer of SENSO 10 Wall stud, we see both sides every day. We supply LVL wall stud products and pine based framing to wholesalers and builders in many regions, so we understand where each system shines.

Wall stud roles in today’s house frames

The stud does much more than hold plasterboard. It carries roof and floor loads, keeps walls straight, supports heavy fittings and helps resist wind and earthquake forces. In modern homes with taller ceilings, big openings and heavier cladding, the demands on each Wall stud increase.

Traditional pine framing still carries many of these loads well. MGP10 pine framing gives a solid base for standard single storey housing. MGP12 structural pine lifts stiffness and strength for heavier roofs or longer spans.

At the same time, design trends have changed. Kitchens run wall to wall with tall cabinets. Bathrooms use large-format tiles. Entry halls stretch longer. In these spaces, even small waves in framing show through. That shift explains why more builders now ask for engineered wood studs in key walls.

SENSO LVL 10 Wall stud sits right in that gap. It gives crews the same simple fixing pattern as pine, yet holds line more firmly, especially in tall or feature walls.

How LVL 10 wall stud works

LVL stands for laminated veneer lumber. Thin wood veneers glue together under heat and pressure to create a single strong section. This process spreads natural defects, such as knots or grain variation, across many layers. The result is a very consistent profile with high strength and reliable stiffness.

Because veneers dry and condition before pressing, movement from moisture change reduces. LVL framing timber stays stable during storage, transport and construction. Over time, it tends to hold shape better than many solid boards. That stability makes LVL wall stud products ideal for walls that receive hard surfaces, heavy fittings or high visual focus.

SENSO LVL 10 follows this logic. We engineer the section for an LVL 10 grade that can act as a direct alternative to MGP10 and a design option against MGP12 pine studs in many layouts. In practice, that means designers can keep familiar spacing while gaining stiffer walls and cleaner lines.

The format still feels like a normal stud. Crews cut, nail and drill it with standard tools. Plates, nogs and lintels all align in the usual way. So builders gain engineered performance without needing a new framing method.

What MGP10 and MGP12 pine framing offer

Machine graded pine remains the backbone of many framing yards. MGP 10 pine framing gives the minimum structural grade for most house frames in markets like Australia. It offers enough strength and stiffness for general wall work, floor plates and low roof loads when used correctly.

MGP12 structural pine increases the design values. The extra stiffness helps in medium spans, heavier roofs and walls that see higher loads. Many builders move between MGP10 and MGP12 when they follow engineering requirements or local practice.

Pine framing brings clear advantages. It is widely available, easy to handle and familiar to every carpenter. It nails and bolts well, and treated versions offer strong termite resistance for internal frames. For simple single storey work, it remains a very cost-effective choice.

However, pine also reflects the limits of solid wood. Each stud comes from one log, with its own knot pattern and grain slope. Some pieces stay straight. Others twist, bow or cup after installation as moisture and temperature move. That variation is the main reason many builders now mix pine with engineered wall framing products.

Wall stud straightness and finish quality

Straightness may sound like a small detail, yet it drives many site headaches. When the frame moves out of line, every trade feels it. Tilers fight lippage. Cabinet makers pack units off the wall. Painters struggle to hide waves under oblique light.

Engineered wood studs, including LVL wall stud lines, help limit those problems. Because veneers carry balanced stresses, these members resist twist and bow far better than typical solid studs. Walls framed with these sections tend to stay flatter from slab to ceiling.

That difference shows up clearly in bathrooms, kitchens and long corridors. Tiled shower walls crack less often. Cabinet lines stay straight, with fewer voids at the back. Plasterboard joints sit flatter, so sanding takes less time and the final finish looks cleaner.

With pine, teams can still achieve straight results, but they usually spend more time sorting packs and straightening frames. They may push bent studs into short cuts, or use them where the wall will hide behind robes. All that sorting and rework carries a labour cost.

SENSO LVL 10 Wall stud aims to reduce that wasted effort. Crews can frame faster because most pieces in the pack meet straightness expectations. They spend more time fixing and less time hunting for a better stick.

Cost, waste and speed on busy sites

On the price list, MGP10 pine framing often sits at the lowest rate per metre. MGP12 structural pine comes next, and engineered studs like LVL 10 usually appear higher. If you only check line rates, pine seems to win every time.

In practice, smart builders look at installed cost, not just supply price. Engineered wood studs reduce hidden costs in several ways. First, waste drops. Packs of LVL and similar products normally contain far fewer rejects, so more of each length ends up in the frame, not in the skip.

Second, labour curves change. Crews frame faster when they can trust the material. They stand, plumb and brace walls in one pass, instead of revisiting sections to pull them back into line. Follow-on trades also move more quickly on flat backgrounds. In tight labour markets, these hours saved matter as much as the timber invoice.

Third, rework and call backs reduce. Issues such as cracked tiles, bowed feature walls or doors that bind all cost time and goodwill. By keeping stud lines true, an LVL 10 Wall stud can lower the risk of these problems. That benefit shows up months or years after handover, when the builder wants to win the next job with the same client.

For wholesalers, SENSO LVL 10 slots in as a premium line above standard pine. It creates a clear step for customers who care more about quality than the lowest possible cost. At the same time, it fits existing stocking and handling systems, so there is no need to change yard practice.

Durability, treatment and moisture behaviour

Moisture change drives much of the movement in frames. Solid studs absorb and release water as conditions shift. When they dry unevenly, twist and bow can appear. Over time, that movement can open joints, stress linings and affect the feel of doors and windows.

LVL responds in a more controlled way. Veneers dry to tight targets before pressing, and adhesive bonds the layers into a single, stable piece. That structure makes the section more resilient and dimensionally stable than many solid equivalents. Wall framing built from engineered studs often shows less movement as seasons change.

Treatment options also matter. In many regions, termite protection for internal framing is now standard. MGP10 pine framing and MGP12 structural pine both come in treated grades that meet those needs. Likewise, LVL wall stud products, including SENSO LVL 10, can receive treatment that aligns with local hazard classes, so designers keep a simple choice between pine and engineered framing at the same protection level.

Because of this, the durability comparison becomes more about stability and performance than basic resistance. Engineered studs usually offer tighter control over shape and stiffness across the life of the building.

Design freedom with tall walls and big openings

Architects and owners now ask for higher ceilings, open living spaces and large window areas. These features place more demand on each framing member. Studs need higher stiffness to carry loads and keep deflection within allowed limits.

Engineered wood studs handle these challenges well. Products such as LVL wall stud systems and LVL T-studs offer high strength-to-weight ratios and excellent stiffness, making them ideal for tall walls, stair voids and large glazed areas.

Pine solutions using MGP10 and MGP12 can still work in many of these cases, especially when designers add more members or tighten spacing. Yet that approach increases material count and complexity. In contrast, an LVL 10 member can sometimes achieve the same result with fewer studs or smaller jambs, depending on the design.

SENSO LVL 10 Wall stud slots into this design story. It provides a simple way for engineers and builders to step up wall performance without changing to an entirely new framing system. The same nailing patterns and layout rules apply; only the capacities change.

When pine still suits the project

Despite the clear benefits of engineered framing, pine keeps a strong role. For simple, low-rise homes with standard ceiling heights and light finishes, MGP10 pine framing often remains the most economical and practical choice. It meets code, comes in familiar sizes and works well with existing tools and skills.

MGP12 structural pine suits mid-range conditions where loads rise but complexity stays low. It provides a useful step before moving to fully engineered systems. Many builders know exactly when their usual details call for that upgrade.

Supply also influences decisions. In some regions, yards hold very deep stocks of pine in core sizes and lengths. If a project needs rapid turnarounds and uses simple geometry, crews may choose pine to keep schedules tight. In other cases, the client may specify pine for cost reasons or for perceived familiarity.

For these reasons, we do not see LVL 10 as a total replacement. Instead, it works best as part of a toolkit. Pine carries simpler, budget-driven work. Engineered studs take the areas where performance, finish and long-term stability matter most.

Why SENSO LVL 10 helps wholesalers and crews

From a merchant’s view, the framing rack needs clear steps, not confusion. You want an entry level line, a mid-tier option and a premium choice, all with easy stories for sales staff. SENSO LVL 10 supports that structure.

Standard MGP10 pine framing covers price-led work. MGP12 structural pine adds strength and stiffness when engineers or builders request a higher grade. SENSO LVL 10 Wall stud then forms the premium option for key walls, high-end homes and demanding commercial interiors. This ladder makes it simple to match product to plan and budget.

Engineered wood studs also help merchants defend market share. When you offer LVL wall stud solutions, you stop customers leaving for competitors that already stock such products. Instead, you become the one-stop source for both pine and engineered framing timber.

On site, SENSO LVL 10 supports a smoother workflow. Crews get straighter material, so frames stand faster and stay closer to line. Plasterers, tilers and cabinet installers work on flatter surfaces and spend less time correcting problems. Over the life of the project, that joined-up performance matters more than a small difference in material price.

Choosing your next wall framing mix

There is no single winner for every frame. The best choice depends on wall height, loads, finish level, labour cost and client expectations. Yet a simple pattern now guides many successful builders and wholesalers.

Use pine as the base material for straightforward, cost-driven walls. Step up to engineered wood studs where movement and straightness matter more, such as bathrooms, kitchens, long corridors, feature façades and tall internal spaces. In these locations, SENSO LVL 10 Wall stud gives the stability, stiffness and clean line that premium finishes demand.

This mixed approach keeps budgets in check while lifting quality where people see and feel it. Owners gain flatter walls, smoother surfaces and fewer issues over time. Builders reduce call backs and protect their reputation. Wholesalers increase average order value and deepen ties with customers.

In the end, the question is not “pine or LVL.” The smarter question is “where does each product work hardest for the project.” Once you answer that, the role of SENSO LVL 10 Wall stud in your framing range becomes very clear.

SENSO LVL 10

SENSO LVL 10 for fast, accurate framing. The product suits tall walls and wide openings. Each piece is stable and straight. Moisture control helps jobs in changeable weather. Termite treatment protects homes in risk zones. Edges are clean for fast fixing. LVL studs keep layouts true during sheathing. LVL studs also reduce site waste and rework. The range matches common wall stud framing sizes. Supply is steady for large projects.

Post time: Dec-01-2025