Wall framing and why it matters more than ever

Every project starts with a frame. That wall framing sets the lines for every finish that follows. If the frame twists or bows, the problem flows through plasterboard, tiles and joinery.

Building codes in markets such as Australia treat framing as a structural backbone. MGP10 pine framing often forms the minimum level for standard housing work. MGP12 structural pine steps up for heavier loads or longer spans in key walls and roof areas.

At the same time, designs keep changing. Higher ceilings, wide openings and hard, glossy finishes now appear even in entry level homes. Those trends push traditional framing harder. Small alignment issues become very visible under sharp light or large format tiles. That is why more designers and builders look beyond basic pine and think seriously about LVL framing systems.

LVL 10 wall framing and how it works

Laminated veneer lumber sits at the heart of SENSO LVL 10 wall framing. Thin veneers peel from logs, then dry to a controlled moisture level. The layers glue together with all grains running in one direction.

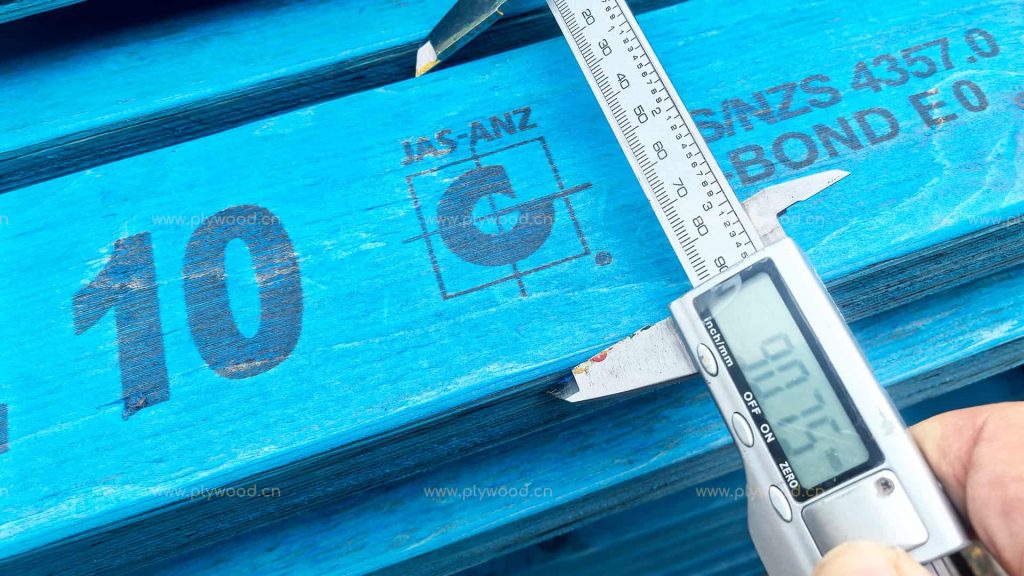

This layup creates a straight and uniform section with predictable strength and stiffness. Natural defects such as knots spread through the thickness and lose their impact. The process gives LVL studs and plates far tighter performance bands than many sawn members.

SENSO LVL 10 wall framing uses this technology to give a premium stud package. The product arrives straight, dimensionally accurate and ready for standard tools. Carpenters cut, nail and drill it like pine. They do not need special blades or fixings for normal residential work.

Because the material behaves so consistently, engineers can design with confidence. They can reach higher walls and wider openings without complex stud patterns in many layouts. That benefit grows when loads combine from upper floors, heavy roofs and external cladding.

Pine framing MGP10 and where it fits

MGP10 pine framing still dominates many structural racks. It is machine graded pine that meets defined strength and stiffness values. This grading makes it suitable for general wall frames, trusses and other load bearing parts.

Builders know this grade well. It cuts easily, nails fast and works with every standard detail. Supply remains broad, with common sizes such as 70×35 and 90×45 available in multiple lengths. For simple single storey homes and light finishes, MGP 10 provides a sound, cost effective base.

However, the timber still reflects its natural origin. Each piece comes from one log, with its own grain pattern and knot cluster. Even with machine grading, stiffness and movement vary within the pack. Some studs stay very straight. Others twist or bow once the frame stands and the climate changes.

That variation creates extra work on site. Crews sort packs, move weaker pieces into short studs, then spend time straightening long walls. Those hours do not show on the timber invoice. They do show in the final labour cost and call back rate.

Pine framing MGP12 for higher loads

MGP12 structural pine extends the same system. It carries higher design values than MGP10 and suits more demanding parts of the frame. Builders often use it in heavier roofs, upper floors or areas with high wind loads.

Many merchants stock MGP 12 in key sizes such as 90×35 or 90×45. The grade offers a useful middle step between basic framing and full engineered solutions. It keeps the same handling feel as MGP10, so crews do not change tools or habits.

Yet MGP12 still behaves like solid pine. Natural variation remains inside the grade band. Moisture movement can also cause twist, bow or length change. In many projects, that movement matters as much as raw strength. Designers may meet code, but still face plaster cracks, uneven tiles and cabinet issues if walls drift out of line.

This is where LVL 10 wall framing makes a clear difference. It gives stiffness and stability close to or above MGP12, yet with far tighter straightness control.

SENSO LVL 10 wall framing vs MGP10 vs MGP12

| Aspect | SENSO LVL 10 wall framing | MGP10 pine framing | MGP12 structural pine |

| Material type | Engineered laminated veneer lumber | Solid pine timber | Solid pine timber |

| Structural band | LVL 10, tight performance range | MGP10 graded pine | MGP12 higher grade pine |

| Straightness | Very straight, minimal twist and bow | Can twist or bow, more sorting | Better than MGP10, still variable |

| Moisture behaviour | Controlled response, high stability | More movement with climate change | Similar to MGP10 behaviour |

| Typical use | Feature walls, tall spaces, tiled areas | Standard housing, cost driven frames | Higher loads, longer spans |

Comparing wall framing straightness and finish quality

Straight walls matter to every trade. When studs line up cleanly, plasterboard joints sit flat. Tiles run true across wet areas. Cabinet lines stay level without deep packers.

LVL framing delivers strong gains here. The lamination process creates members that resist bow, crook and twist far better than many sawn studs. SENSO LVL 10 wall framing arrives with tight straightness tolerances. It tends to hold those lines through storage, erection and fit out.

Pine framing can still achieve good results, yet crews need more effort. They check each length as it comes off the pack. Some sticks move into off cuts or blocking. Others require clamps and straightening before fix off. Over a whole frame, that extra handling slows work and increases fatigue.

By contrast, LVL studs let teams work in a smoother rhythm. Frames stand faster, with fewer problem walls to revisit. Plasterers and tilers notice the change. They see less lippage, fewer hollow spots and cleaner joints. For the builder, that means fewer complaints about crooked corners or wavy hallways months after handover.

Cost, waste and speed with LVL 10 wall frame

On a basic price list, MGP10 often looks cheapest. MGP12 sits higher, and LVL 10 wall framing usually appears as a premium option. However, the smart comparison looks at installed cost, not just dollars per metre.

Waste forms the first hidden gap. Packs of SENSO LVL 10 wall framing usually contain very few rejects. The stability and straightness mean most lengths land inside the frame. Pine packs often produce more off cuts around large knots, checks or severe twist. Skip loads and tipping fees grow with that waste.

Labour forms the second gap. If crews spend time sorting, straightening and packing, the real cost of a “cheap” frame rises fast. LVL studs reduce that noise. Carpenters stand walls, lock them plumb and move on. Downstream trades also save time because backgrounds stay flatter.

Rework forms the third gap and often hurts the most. Call backs for cracked tiles, binding doors or bowed feature walls all erode profit and trust. LVL 10 systems reduce movement and improve long term alignment. For many builders, that smoother after sales period is worth more than the material difference on day one.

Durability, treatment and moisture in timber frame walls

Framing durability starts with the right treatment and moisture behaviour. MGP10 and MGP12 pine both come in H2 termite treated options for indoor, above ground use. These grades give long term protection in many housing markets.

LVL products can match that protection. Many suppliers offer glue line and surface treatment that reaches the full section. SENSO LVL 10 wall framing can align with local hazard classes, so specifiers keep simple rules. They can choose between pine and LVL on performance, not on basic durability.

Moisture movement creates a different challenge. Solid studs expand and shrink as conditions change. Uneven drying can lead to twist, bow and gap growth at joints. LVL layups manage this risk better. Pre dried veneers and full depth bonding help the member respond more evenly. Over time, that stability supports tighter joints and steadier lines.

Design freedom and tall walls with LVL systems

Design trends keep pushing wall framing harder. Higher ceilings, stacked windows and wide openings look great, yet they increase loads and deflection risks. Studs must carry forces and still keep linings flat.

MGP10 pine framing can handle many basic layouts, yet tall or heavily loaded walls may demand closer spacing or heavier sections. MGP12 improves capacity but still carries the natural variation of solid wood.

SENSO LVL 10 wall framing answers these demands with reliable stiffness and high strength. Engineers can design tall walls, stair voids and large glazed areas with more confidence. In some layouts, they can reduce stud counts or avoid complex stud clusters around large openings.

LVL systems also integrate well with engineered beams and I-joists. Load paths remain clear and predictable. This integrated approach suits modern, prefabricated and panelised framing methods, where accuracy and repeatability matter as much as raw capacity.

When pine framing still makes sense

Despite the clear benefits of LVL 10 wall framing, pine still deserves a strong place. Straightforward single storey houses with modest spans and lighter finishes often perform very well with MGP10. It remains the minimum grade for structural framing in many regions and offers good value when used within its limits.

MGP12 structural pine helps when loads and spans rise, yet design complexity stays low. It forms a useful step between standard frames and full engineered wall systems. Many builders choose it on habit, local practice or client requests.

Hybrid framing now appears on many smart projects. Internal partitions and low risk walls use pine. High impact zones such as bathrooms, kitchens, long corridors and feature façades upgrade to SENSO LVL 10 wall framing. This mix keeps budgets under control while lifting performance where owners will notice most.

How SENSO LVL 10 wall frames helps wholesalers and builders

Merchants need a clear story, not just another stock line. LVL 10 wall framing lets you build a simple three step ladder. MGP10 offers the base level for cost driven work. MGP12 covers mid tier demands. SENSO LVL 10 wall framing then becomes the premium option for high value or high risk walls.

This structure gives sales teams easy language. They can match product choice to ceiling height, finishes and client expectations in a few questions. That approach protects margin and keeps good builders tied to your yard instead of shopping around for engineered options.

For builders, the value sits on site. SENSO LVL 10 wall framing reduces sorting time, speeds framing and cuts rework. Plasterers, tilers and cabinet makers all feel the difference under their hands. Fewer defects reach the client, and fewer call backs eat up weekends. Over time, those outcomes build a stronger brand and steadier referral stream for everyone involved.

Choosing the right wall framing mix for the next project

Every frame tells a story about choices. Some walls only need basic strength. Others must hold shape under heavy loads and hard scrutiny. Instead of chasing one perfect material, smart teams now use a mix.

Use MGP10 and MGP12 pine where loads stay modest and finishes forgive slight movement. Bring SENSO LVL 10 wall framing into bathrooms, kitchens, tall living spaces and long external walls. In those areas, straighter members, higher stiffness and better stability protect both finish quality and reputation.

This balanced strategy keeps the supply chain simple while lifting performance where it counts. Wholesalers sell a complete framing package, not just a price. Builders gain calmer sites and more predictable jobs. Owners walk into homes that still feel solid and straight many years later. That is the true promise of pairing pine with SENSO LVL 10 wall framing in one smart, flexible framing system.

LVL Timber

In the realm of commercial construction, structural integrity is paramount. SENSO Laminated Veneer Lumber (LVL) beams, recognized for their superior strength and durability, play a significant role in building robust structures that withstand the test of time.

Unveiling SENSO LVL Timber

SENSO LVL Timber are crafted with meticulous precision, harnessing the strength of laminated wood. These beams, renowned for their structural features like cross-orientation, superior strength, stiffness, and dimensional stability, redefine construction standards.

SENSO LVL Advantages in Commercial Construction

ROCPLY LVL Beam bring multiple benefits to commercial construction:

- Superior Strength and Stability: SENSO LVL Timber ensure buildings are robust, long-lasting, and resilient.

- Flexibility and Customization: Our LVL Beams can be tailored to suit diverse construction requirements.

- Cost-Effectiveness: SENSO strikes the perfect balance between quality and affordability.

- Sustainability: We uphold green practices, ensuring our products are environmentally friendly.

- Moisture and Fire Resistance: SENSO Structural LVL are designed to resist moisture and fire, enhancing safety.

- Variety and Aesthetic Appeal: We offer a range of sizes and decorative options, catering to various aesthetic needs.

Adherence to Industry Standards

SENSO commitment to quality shines through in our adherence to strict JAS-ANZ standards. Our laminated wood LVL surpass these standards, reinforcing our commitment to delivering high-performance and reliable products.

LVL Timber: Enhancing Structural Integrity

SENSO LVL Beams are vital to maintaining a building’s structural integrity. With outstanding load-bearing capacity, shear strength, dimensional stability, and resistance to humidity, our LVL Beam uphold the structural rigidity of buildings, meeting diverse architectural demands.

Diverse Industries and Applications

SENSO LVL Timber are embraced across numerous industries, including commercial construction, interior design, furniture manufacturing, and many more. The superior quality and versatility of our products make them the first choice for various applications.

Choose SENSO LVL Timber

ROCPLY LVL Beam are a testament to our unwavering commitment to quality, performance, and sustainability. They enhance the structural integrity of commercial buildings while catering to diverse architectural needs. Discover more about SENSO range of LVL timber products, connect with our sales team, or make your purchase today – we’re ready to redefine your construction experience.

Post time: Dec-10-2025