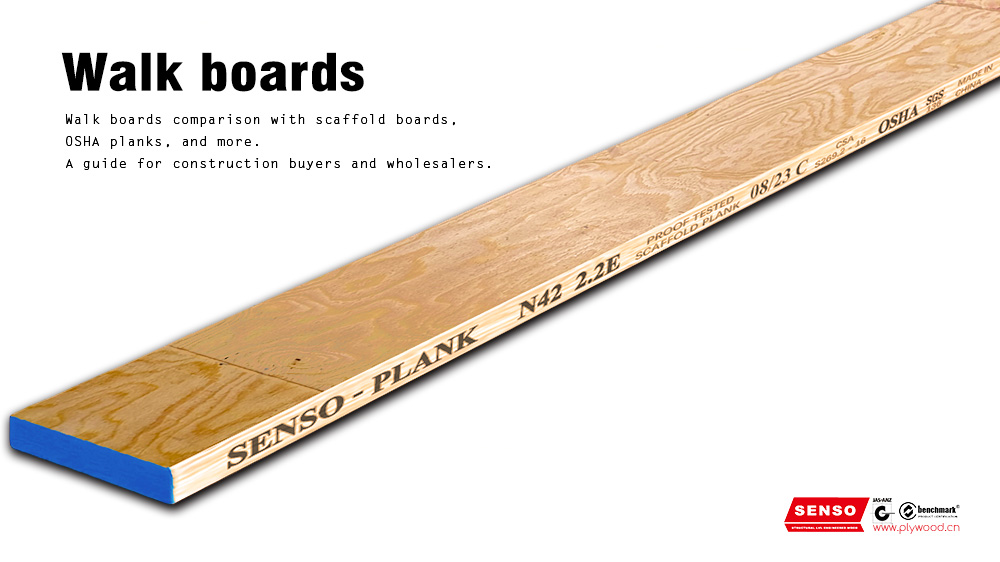

What Are Walk Boards?

Walk boards are temporary platforms placed between scaffold structures or supports. Workers stand or move on them while working at height. These boards create a flat, stable area to walk, stand, or place tools. Walk boards are available in various forms, including wood, aluminum, and composite materials. Many walk boards have slip-resistant surfaces or built-in safety hooks. Some are made for specific load ratings and site conditions, including wet or windy weather. Compared with standard scaffold planks, walk boards offer better comfort and a wider walking surface. They also often meet stricter safety requirements. Builders use them for construction, building maintenance, and warehouse work.

Walk Boards vs Scaffolding Plank

Both are used for working at height, but the design and use of scaffold board and scaffolding planks differ.

Walk board provide a wide, flat, and often reinforced walking surface. They are engineered for strength and stability. Aluminum walk boards, in particular, cut weight and make handling easier. Some walk boards also have built-in side locks or anti-slip textures.

Scaffolding planks are generally wood-based and simpler in structure. They may lack built-in anti-slip features or edge protection.

Comparison Points:

- Walk board support higher loads.

- Scaffolding planks are typically more affordable.

- Walk board last longer in harsh environments.

Scaffolding planks are suitable for temporary or lower-budget projects. Walk board perform better on busy, high-traffic sites.

✅ Walk Boards vs Scaffold Board

These two terms are often used interchangeably, but they aren’t the same.

Scaffold boards are commonly made from pine, fir, or laminated timber. In some regions, scaffold boards must meet specifications such as BS 2482 or OSHA.

Walk boards are more versatile in design. They often have a steel or aluminum frame and a durable deck.

Key Differences:

- Scaffold boards tend to be timber-based and straightforward.

- Walk board come in different materials and often offer better grip.

- Walk board typically handle more wear and tear.

Walk boards suit high-use sites and multi-shift work. Scaffold boards can work for small jobs or short-term fixes.

✅ Walk Boards vs OSHA Planks

In the U.S., scaffolding platforms must comply with OSHA standards. OSHA planks are graded, stamped, and tested.

OSHA planks refer to wood planks that meet load and strength standards. They are often made from dense timber with strict defect limits.

Walk boards can meet OSHA requirements when they are tested and clearly labeled. These versions often include safety features such as edge brackets or anti-slip coatings.

Notable Points:

- OSHA plank have clearly defined strength requirements.

- Walk board can exceed OSHA standards if built accordingly.

- OSHA-approved walk board offer peace of mind and legal compliance.

If your jobsite is governed by OSHA, verify that walk board or scaffold planks have certification.

✅ Walk Boards vs Aluminum Walk Board

Aluminum scaffold boards are a specialized option. They are light to handle and resist corrosion.

Standard walk board can be made from timber or hybrid materials. They may be heavier and more prone to weather-related damage.

Aluminum walk board:

- Are easier to move and reposition.

- Resist rust and weather damage.

- Usually last longer.

These boards are ideal for outdoor and mobile scaffold systems. The higher initial cost is offset by reduced replacement needs.

✅ Walk Boards vs Scaffold Decking

Scaffold decking is a broader term. It includes all platforms used in scaffold setups.

Scaffold decking may refer to:

- Plywood decks

- Steel platforms

- Modular planks with hooks

Walk board fall within this category but usually refer to portable planks. Scaffold decking may be heavier or modular.

Difference Summary:

- Walk boards are more portable.

- Scaffold decking is often custom-fit to frames.

- Decking systems may include side rail integration.

Walk boards work best in adjustable scaffold systems. Fixed scaffold decks suit large, long-term scaffold setups.

Walk Boards in Different Industries

Walk boards are used across diverse sectors. Each application has unique safety and performance requirements.

Construction Sites

This is the most common use. Workers use walk board between scaffold frames. They need a stable, anti-slip surface for safety. Boards must handle heavy foot traffic, tools, and materials.

Industrial Maintenance

Factories and warehouses use walk board for lighting, ceiling, and HVAC tasks. Aluminum walk board work best due to easy setup and corrosion resistance.

Event Setup and Stage Building

Scaffold boards support temporary walkways and platforms. Lightweight aluminum options allow fast setup and easy removal.

Facade Cleaning and Painting

Professionals prefer anti-slip walk boards with hooks. These prevent accidental shifts during movement at height.

Shipbuilding and Aerospace

Custom scaffolding plank with narrow widths or curved profiles are used. They support work in confined or high-precision zones.

Each industry needs walk boards tailored for specific conditions. Proper selection increases efficiency and reduces risk.

✅ Price and Durability Comparison

Buyers often compare walk boards based on price and lifespan. Here’s how different types stack up.

Wood-Based Walk Boards

- Price: Low

- Durability: 1–2 years

- Pros: Affordable, easy to replace

- Cons: Prone to warping, rot, and splinters

Plywood Decked Boards with Steel Frames

- Price: Medium

- Durability: 2–4 years

- Pros: Better strength, less flex

- Cons: Heavier, affected by water if unsealed

Aluminum Walk Boards

- Price: High

- Durability: 6–10 years

- Pros: Lightweight, rustproof, weather-resistant

- Cons: Higher upfront cost

Aluminum walk boards offer the best long-term value for high-use sites. Wood suits smaller or short-term projects.

✅ How Long Do Walk Boards Last?

The lifespan of scaffolding plank depends on use, storage, and climate.

- Indoor use: Boards can last twice as long due to reduced exposure.

- Proper storage: Dry, clean areas extend life.

- Daily use sites: Boards can wear out faster, especially on high-use sites. Choose aluminum boards or steel-reinforced models for longer service life.

Lifespan Range by Material:

- Basic wood planks: 1–2 years

- Plywood with edge seal: 3–4 years

- Aluminum scaffold board: Up to 10 years

Well-maintained walk boards reduce replacement costs and improve safety outcomes.

✅ Walk Boards Preferences by Region

Global markets favor different types of walk boards based on climate, regulations, and cost factors.

United States

OSHA-compliant scaffolding plank and planks are essential. Most use stamped timber or aluminum with load rating tags.

Australia

High UV and wet weather favor galvanized steel or aluminum walk boards. Lightweight and corrosion-proof materials dominate.

Europe

Projects follow EN scaffold standards. Walk boards are often plywood with steel frames for durability.

Middle East

Heat and dust make aluminum scaffolding plank a top choice. Their light weight is ideal for fast-moving teams.

Africa

Mixed use of wood and aluminum walk boards depending on budget and project type. Demand is rising for safer, long-lasting options.

Adaptability to climate and regulation shapes product demand in every market.

✅ What to Look for When Buying Walk Boards

Choosing the right walk board requires more than checking the price tag.

1. Load Capacity

Confirm load rating. Common options range from 250 to 1,000 lbs.

2. Size and Width

Choose the correct length and width to match your scaffold frames.

3. Surface Material

Slip-resistant textures add safety. Metal grating or film-faced plywood are common.

4. Weather Resistance

Aluminum or treated plywood performs better outdoors.

5. Certification

For OSHA or BS standard jobsites, choose boards with visible compliance stamps.

Buyers should also consider availability, replacement cycle, and transport weight.

Walk Boards Make Jobsites Safer

Walk boards are more than just planks. They are enIf OSHA rules apply on your jobsite, verify that your walk boards or scaffold planks have valid certification. gineered to support safe, productive work at height. Whether you choose wood, aluminum, or hybrid types, each offers specific benefits.

- Use scaffolding planks for short jobs and budget control.

- Choose scaffold boards for regulated wooden platforms.

- Go with OSHA plank when working under U.S. law.

- Pick aluminum walk board for top-tier performance and longevity.

The best walk board fits your jobsite, budget, and safety needs. Contractors and wholesalers benefit from knowing these options.

Post time: Jul-30-2025