What is Scaffold Planks Wood?

Scaffold planks wood refers to wooden boards designed to support workers and tools on scaffolding structures. To ensure safety, these planks must meet strict strength and performance standards. They are commonly used on construction sites, industrial projects, and in shipyards. Scaffold planks are typically made from Southern Yellow Pine, Douglas Fir, or other dense, high-performance timber species. In addition, these planks are usually OSHA-compliant and come in both treated and untreated options, providing flexibility for various job-site needs. Buyers often choose scaffold plank wood for its load-bearing reliability, affordability, and ease of handling compared to metal alternatives.

Why Scaffold Planks Wood Remains a Global Standard

Wooden scaffold planks have been used in construction for decades. Why? They provide an unmatched balance between weight, strength, and cost. As a result, they remain a reliable choice for many construction projects, offering both performance and value.

High-quality scaffold planks provides a firm walking surface. When treated correctly, these planks resist moisture, mold, and insects. That makes them a go-to product for construction managers across climates.

Even with the rise of aluminum or composite boards, scaffold plank wood still leads in sales. Especially in regions like Southeast Asia, the Middle East, and North America, construction companies continue to trust wood for high-rise and infrastructure projects.

Comparing Scaffold Planks Wood vs. Metal Boards

Let’s break down how scaffold planks stacks up against other materials.

| Feature | Scaffold Planks Wood | Metal Scaffold Boards |

| Weight | Lightweight, easy to carry | Heavier, harder to transport |

| Cost | Affordable, budget-friendly | Expensive upfront |

| Grip | Naturally non-slip | Can be slippery when wet |

| Flexibility | Has slight give underfoot | Very rigid |

| Durability | Requires treatment | Rust-resistant but dent-prone |

| Maintenance | Needs checking for cracks | Needs rust inspection |

Scaffold plank wood outperforms in price and comfort. But proper inspection is essential to ensure safety during use.

Types of Wood Used in Scaffold Planks

Southern Yellow Pine (SYP)

Known for its strength and stiffness. SYP is often kiln-dried and treated to meet OSHA standards.

Douglas Fir

Lightweight and durable, Douglas Fir is preferred for its dimensional stability and smooth grain.

Radiata Pine

Common in Australia and New Zealand. It’s treated for water and insect resistance.

Mixed Hardwood

Some scaffold planks use hardwood species for added strength, especially in humid or high-load regions.

Each wood type offers different benefits. Buyers must balance budget, application, and climate when choosing.

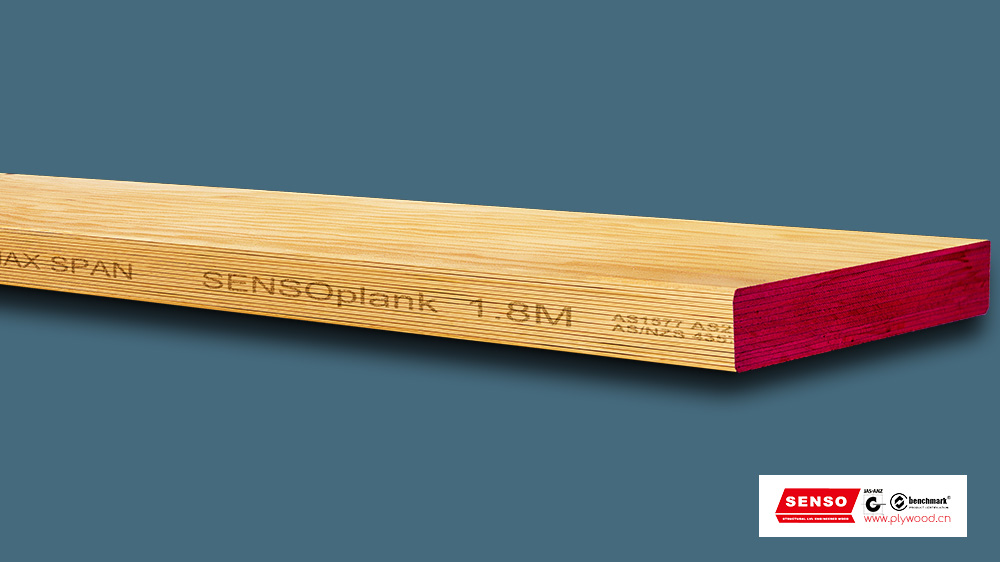

Why Choose SENSO Scaffold Planks Wood?

SENSO supplies premium scaffold plank wood that meet international OSHA and EN standards. Here’s what sets our planks apart:

FSC-certified timber

High load-bearing capacity

Water- and insect-resistant treatments

Custom lengths and thicknesses

Smooth finish for slip resistance

SENSO scaffold planks is trusted in more than 40 countries. Our clients include large construction contractors, scaffolding rental companies, and import wholesalers.

Where Scaffold Planks Wood Is Used

Scaffold planks wood is a vital part of jobsite safety. Here are the most common application scenarios:

1. High-Rise Construction Sites

Used to create walkable surfaces between scaffold frames. Workers rely on scaffold plank wood for footing and stability.

2. Industrial Maintenance Projects

Whether in oil refineries or shipyards, walk boards support tool loads and technician access.

3. Infrastructure Works

Scaffold plank wood is often used in bridge maintenance, power line construction, and large-scale civil engineering works.

4. Home Renovation and Exterior Jobs

Painters and builders often prefer wooden walk boards for their grip and handling ease during facade work.

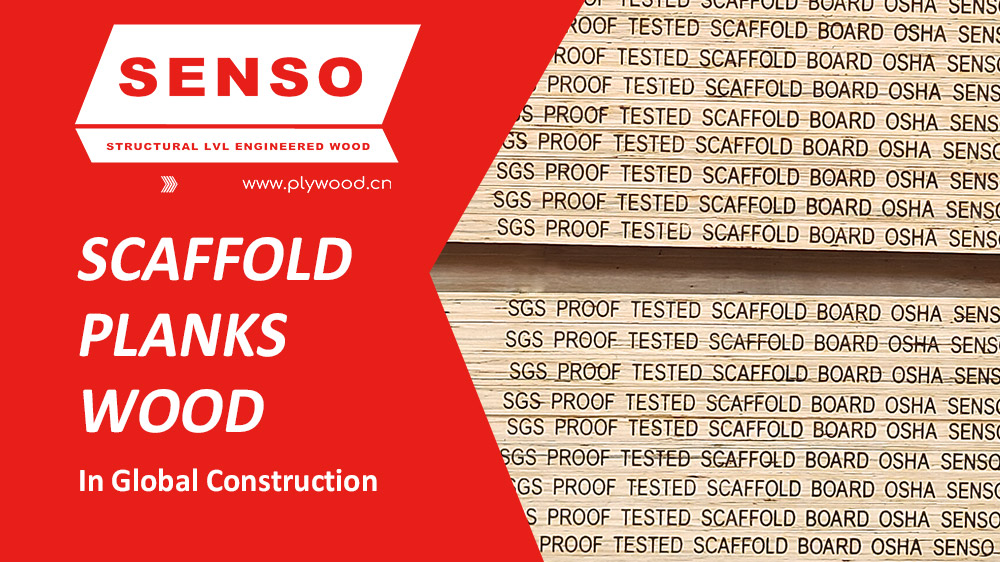

How to Identify OSHA-Grade Scaffold Planks Wood

OSHA-compliant scaffold planks must meet rigorous quality standards. Here’s what to check:

Stamping or Marking: Look for stamps showing compliance with ANSI A10.8 or OSHA 1926 Subpart L.

Grade: Only select planks labeled as scaffold grade, such as SYP DI65 or equivalent.

Treatment: The wood should be heat-treated or chemically treated to resist rot and insects.

End Seals: Quality scaffold plank wood often includes sealed ends to reduce splitting and water intrusion.

No Major Defects: Avoid planks with knots, splits, or cracks longer than 6 inches.

SENSO scaffold planks meets all OSHA requirements. Each batch is tested, stamped, and certified before shipment.

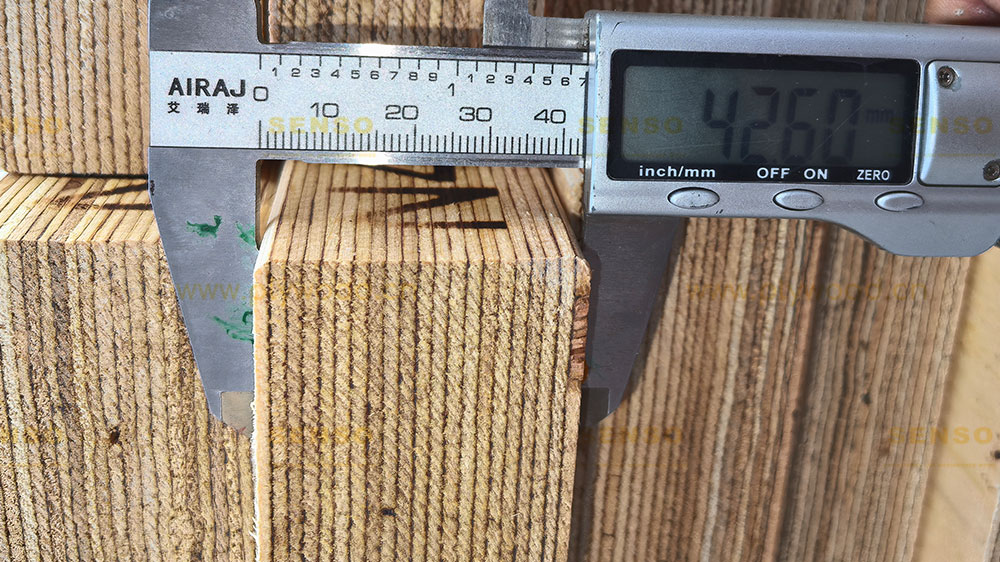

Standard Sizes for Scaffold Planks Wood

Global scaffold users commonly request these dimensions:

Thickness: 38mm / 1.5 inch

Width: 225mm / 9 inch

Length: 2.4m, 3.0m, 3.9m, 4.0m

In the U.S. and Australia, scaffold planks wood often follows regional standards for thickness and treatment. SENSO offers customization for international orders.

Key Benefits of Scaffold Plank Wood for Buyers

For wholesalers and site managers, choosing scaffold plank wood offers multiple advantages:

Lower Upfront Cost than composite or steel alternatives

Local Repairability—damaged planks can often be repaired on site

Eco-Friendly when sourced from FSC-certified forests

Easier Handling due to lighter weight

Natural Friction Surface offers better safety

For bulk buyers, SENSO provides volume discounts, FSC documentation, and flexible shipping options worldwide.

Buying Tips: How to Source Quality Scaffold Planks Wood

To get the best performance and safety:

Insist on Certification

Always request mill certificates, OSHA compliance, and treatment records.

Check Moisture Content

Kiln-dried planks perform better. Target 15–19% moisture content for stability.

Order in Bundles

Bulk orders reduce freight cost per unit and simplify unloading on-site.

Avoid Over-Storage

Store planks in dry, shaded areas with airflow to prevent warping or mold.

Work With Experienced Suppliers

Manufacturers like SENSO understand your needs and can deliver consistently high-quality scaffold planks wood at scale.

Why Scaffold Planks Wood Remains the Preferred Choice

Despite the market’s move toward metal and composite boards, walk board holds firm. Its balance of durability, price, and performance keeps it in high demand globally.

SENSO continues to lead in producing OSHA-approved scaffold plank wood for buyers across industries. Our commitment to quality, timely delivery, and adherence to international standards has earned us the trust of contractors and wholesalers in over 40 countries. Because of this, we are a preferred supplier for projects worldwide, ensuring consistent performance and customer satisfaction.

If you’re sourcing reliable scaffold planks wood, SENSO is your go-to partner.

Post time: Aug-11-2025