Why LVL beam sizes drive performance

Section LVL beam sizes controls stiffness and strength. Depth limits deflection, which protects floor comfort and roof lines. Width supports bearing, fixings, and connectors. Correct sizing avoids bounce, cracks, and noisy floors. It also reduces temporary props and rework. A good pick saves time across the whole job. In turn, that cut in labour often beats a lower beam price.

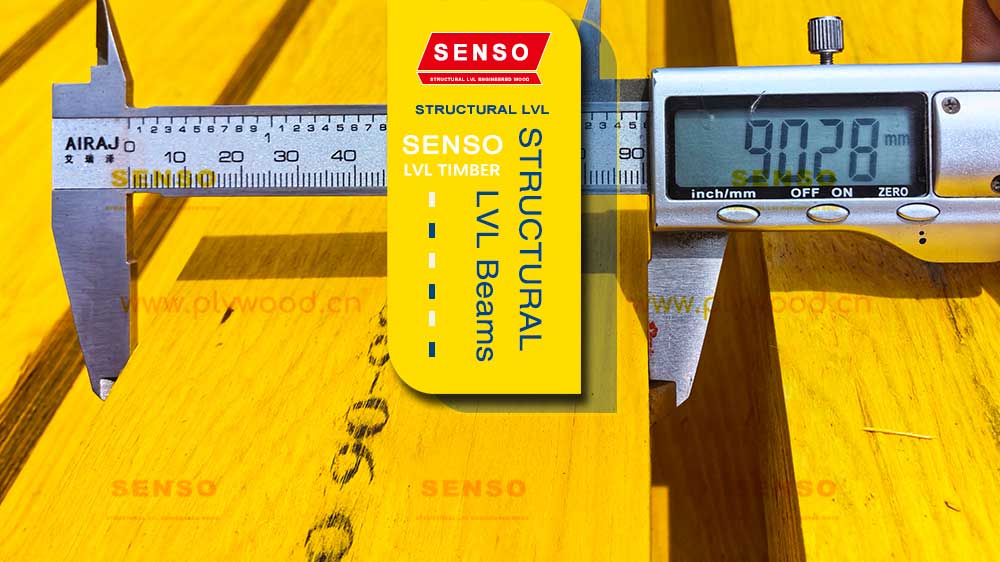

SENSO LVL beam sizes at a glance

SENSO holds a practical grid of sections in stock. Widths cover 45, 63, 75, 90, and 120 mm. Depths progress through 150, 200, 240, 300, 360, 400, and 450 mm. Lengths run up to 12 metres for clean spans. The grid aligns with hangers and brackets from major brands. That fit speeds install and limits on site trimming. Custom lengths are available on request to cut waste.

Quick reference table

| Width (mm) | Depth (mm) | Typical uses |

| 45 | 150 | Trimmers and short lintels |

| 63 | 200 | Floor joists and small headers |

| 75 | 240 | Deck beams and garage openings |

| 90 | 300 | Main floor beams and ridge beams |

| 120 | 360–400 | Long headers and carry beams |

These lines match common LVL dimensions used by designers. Crews gain speed when hangers and bolts align without shims. The result is a straighter frame and a cleaner finish.

How spans relate to LVL beam sizes

Span capacity depends on load, grade, and service class. Designers also check vibration and long term creep. You should confirm final picks with an engineer. Still, early planning needs ballpark spans. Use the table below as a guide for typical floor loads and common deflection limits.

Approximate spans by size and grade

| Size (mm) | Grade | Spacing | Approx span (m) |

| 63 × 200 | LVL E13 | 600 mm | 3.0–3.6 |

| 75 × 240 | LVL E14 | 600 mm | 3.6–4.5 |

| 90 × 300 | LVL E15 | 600 mm | 4.5–5.6 |

| 120 × 360 | LVL E15 | 600 mm | 5.6–6.6 |

| 120 × 400 | LVL E16 | 600 mm | 6.6–7.2 |

Values shift with live load, point loads, and bracing. Wind uplift also affects roof members. Therefore, treat these figures as planning guides only. Use approved LVL span tables and local codes for final designs.

Picking LVL beam sizes by load case

Every project includes light, medium, and heavy zones. You should match size to use, not just to span. Lighter areas allow short depths and narrow widths. Heavy areas need depth first, then width.

Light duty jobs include trimmers, small lintels, and deck edges. Sections like 45 × 150 and 63 × 200 handle these runs. Keep spans short and watch vibration at edges.

Medium duty zones cover garage openings, floor carry beams, and studs. Sizes such as 75 × 240 or 90 × 300 strike a balance. These sections meet strength and deflection while staying cost effective.

Heavy duty work includes long headers, ridge beams, and carry lines. Sections like 120 × 360 or 120 × 400 offer the control you need. Higher grades such as E15 or E16 help reduce depth for tricky constraints.

SENSO can mix these sizes into staged packs. That approach speeds install and reduces yard handling. Your site gets the right beams at the right time.

LVL beam sizes versus solid timber beams

Solid timber beams may shrink and cup as moisture changes. Grain variation can cause twist or bow under load. LVL solves these issues with thin, bonded veneers. The structure stays uniform along the whole length. You get reliable design values, straight lines, and consistent weight per metre. Fixings bite cleanly and hold predictably. That uniformity helps crews drill, bolt, and hang without surprises.

Solid cuts still suit rustic looks and very short spans. Yet LVL dominates where planners need reach and control. Supply chains also prefer repeatable packs with clear markings. That transparency helps yards track stock and cut losses.

Grades, treatments, and code notes

Regional standards define design values and quality control. AS NZS 4357 guides structural LVL in Australia and New Zealand. Designers then apply AS 1720 or similar texts for design checks. North American jobs may use the NDS framework. European projects often reference Eurocode rules. SENSO supplies mill certificates, labels, and test data with each pack. Your documents will match the destination and the project need.

Some sites require treatment or edge sealing. Termite zones may need H2 or higher classes. Coastal builds can call for extra end sealing and wrap. You should store packs off the ground with cover and airflow. Good storage protects edges and faces from damage. That care preserves planed tolerances until install.

A simple workflow for LVL beam sizes

You can select sections quickly with a repeatable path. Start with span, load, and spacing. Confirm deflection targets for floors and roofs. Set grade to meet strength and creep. Choose depth to control deflection. Adjust width for bearing and connectors. Lock the length range for lifts and access. The last step confirms hole zones, hangers, and fixings.

SENSO supports this process with rapid takeoffs. You can send drawings and basic loads. Our team returns options that hit the brief. We also include alternates that reduce waste or lead time. That support helps estimators close quotes with confidence.

Floor frames and practical section picks

Floors need stiffness for comfort and finishes. Depth does most of the work in these spans. Common living areas suit 75 × 240 and 90 × 300. Larger spaces lean toward 120 × 360 for clean lines. Edge beams sometimes need extra width for bolts and hangers. Match LVL sizes to services to avoid clashes. Keep holes within permitted zones and distances. SENSO can mark hole zones on drawings to save time.

Typical floor beam snapshots

| Room type | Typical size | Notes |

| Bedroom | 63 × 200 | Short spans and light loads |

| Living area | 75 × 240 | Comfort focused deflection targets |

| Open plan | 90 × 300 | Longer spans with vibration control |

| Large hall | 120 × 360 | Crowd loads and long lines |

These picks are starting points only. Final checks should reflect floor build ups and finishes. Heavy tiles or stone raise dead load and may shift the size.

Roof members and ridge choices

Roofs see wind, uplift, and long clear runs. Depth and grade control ridge deflection and finish lines. Many homes trust 90 × 300 for standard ridges. Larger spans often use 120 × 360 or 120 × 400. Purlins in light sheet roofs may sit at 63 × 200. Heavier roofs step up one size for margin. Bracing and tie down hardware should match the beam width. SENSO can supply brackets and fixings as a kit. That service trims time at height and helps crews stay safe.

Typical roof beam snapshots

| Roof part | Typical size | Reason |

| Ridge | 90 × 300 | Controls mid span deflection |

| Hip or valley | 75 × 240 | Manages compound load paths |

| Purlin | 63 × 200 | Suits light sheet cladding |

| Long ridge | 120 × 360 | Meets strict line targets |

Always set tie downs and bracing during design. Later changes can cause holes near high stress zones. Plan now and avoid those risks on site.

Handling, weight, and logistics planning

Weight per metre guides lift plans and crew sizes. Actual mass depends on species and grade. Use the table below as a planning aid. Confirm final numbers with your supplier before crane day.

Approximate weight per metre

| Size (mm) | kg per m |

| 63 × 200 | 9–10 |

| 75 × 240 | 13–15 |

| 90 × 300 | 20–23 |

| 120 × 360 | 32–36 |

| 120 × 400 | 36–41 |

Longer pieces need care to avoid edge damage. Use slings with corner protectors and balanced pick points. Keep packs strapped until the moment of use. SENSO labels pack balance points for safer forklift moves. Ask for half packs if the site has tricky access. Smart logistics cut risk and reduce labour hours.

Cost and value across section choices

Larger sections and higher grades cost more per metre. Yet the cheapest beam rarely delivers the lowest job cost. The right size can remove props or secondary steel. Crews move faster when spans work the first time. Waste also matters in the final number. Custom lengths can save many cuts and hours. SENSO keeps popular sizes on the floor to reduce lead time. That stock depth helps buyers hit tight dates without compromise.

Frequently asked questions on LVL beam sizes

How should I choose between 75 × 240 and 90 × 300

Start with span, load, and deflection. If deflection fails, increase depth. If bearing fails, increase width. Confirm the result with an engineer.

Do longer delivered lengths change my section choice

The structural demand depends on clear span, not delivery length. Long pieces need better handling plans. Check access and lifting early in the process.

Can I rip or notch an LVL on site

Avoid rips that reduce depth. Small notches may be possible with written approval. Follow the design and the supplier guide before any cut.

Which grade should I request for general use

Pick the lowest grade that meets checks. E13 suits short spans and light loads. E15 covers many carry beams. Long runs or tight limits may need E16.

How do I read LVL span tables without wasting time

Define load and deflection limits first. Find the span and spacing that match the job. Read across to size and grade. Ask SENSO for a quick review if needed.

Ordering tips and a working pack map

Fast orders share drawings, span notes, and the site schedule. Tell us crane limits and access routes. We can map packs by install stage. Cut lists help reduce saw time and mess. Colour tags also speed finds across the site. Mark beams by stage so crews pull the right pack at once.

Include treatment needs and edge sealing in the request. Ask about moisture wrap for sea freight or wet seasons. SENSO packs carry barcodes, handling labels, and clear stamps. You will receive certificates and mill data in one set. That bundle supports approvals and final inspections.

Example staged pack map for mixed LVL beam sizes

| Stage | Size mix | Quantity | Notes |

| Stage 1 | 63 × 200, 75 × 240 | 60 pcs | Floor joists and small headers |

| Stage 2 | 90 × 300 | 24 pcs | Main carry beams for living areas |

| Stage 3 | 120 × 360 | 12 pcs | Ridge beams and long headers |

| Stage 4 | 120 × 400 | 8 pcs | Garage spans and special runs |

SENSO services that make sizing easier

SENSO supports buyers with simple tools and fast data. Our takeoff team reviews spans and returns options. You get side by side picks for cost and speed. We can suggest small changes that reduce waste. Many jobs save money by moving one step in depth. Others save time by switching grade in a single bay. We share those plays openly, so you can choose with clarity.

Packs leave the mill with clean edge sealing and wrap. Labels include size, grade, treatment, and barcodes. Yards scan the codes to track live inventory. That visibility helps wholesalers plan loads with confidence. Site crews see the same labels and pull beams in the right order.

Final take on LVL beam sizes and next steps

Correct LVL beam sizes set every project up for success. Depth and grade control deflection and creep. Width supports bearing and fixings with margin. Smart choices reduce props, cuts, and add-on steel. SENSO carries a broad grid of stock sections for quick turns. Widths span 45 to 120 mm. Depths range from 150 to 450 mm. Grades run from E13 to E16 for reach and control. You can order custom lengths to cut waste and save hours.

Share drawings and basic loads, and our team will help. We return clear options that meet span and comfort limits. You receive quotes, pack maps, and delivery plans together. Crews then lift, place, and fix with fewer surprises. That is how strong frames rise on time and on budget.

Quote checklist

- Marked spans and spacing by zone

- Live and dead loads for each line

- Target grade and treatment class

- Known size preferences if any

- Length ranges and cut lists

- Delivery windows, access, and crane limits

Important note: Use LVL beam sizes as a planning term only. Lock final selections with a qualified engineer. Local standards and site conditions control the final word.

LVL Timber

In the realm of commercial construction, structural integrity is paramount. SENSO Laminated Veneer Lumber (LVL) beams, recognized for their superior strength and durability, play a significant role in building robust structures that withstand the test of time.

Unveiling SENSO LVL Timber

SENSO LVL Timber are crafted with meticulous precision, harnessing the strength of laminated wood. These beams, renowned for their structural features like cross-orientation, superior strength, stiffness, and dimensional stability, redefine construction standards.

SENSO LVL Advantages in Commercial Construction

ROCPLY LVL Beam bring multiple benefits to commercial construction:

- Superior Strength and Stability: SENSO LVL Timber ensure buildings are robust, long-lasting, and resilient.

- Flexibility and Customization: Our LVL Beams can be tailored to suit diverse construction requirements.

- Cost-Effectiveness: SENSO strikes the perfect balance between quality and affordability.

- Sustainability: We uphold green practices, ensuring our products are environmentally friendly.

- Moisture and Fire Resistance: SENSO Structural LVL are designed to resist moisture and fire, enhancing safety.

- Variety and Aesthetic Appeal: We offer a range of sizes and decorative options, catering to various aesthetic needs.

Adherence to Industry Standards

SENSO commitment to quality shines through in our adherence to strict JAS-ANZ standards. Our laminated wood LVL surpass these standards, reinforcing our commitment to delivering high-performance and reliable products.

LVL Timber: Enhancing Structural Integrity

SENSO LVL Beams are vital to maintaining a building’s structural integrity. With outstanding load-bearing capacity, shear strength, dimensional stability, and resistance to humidity, our LVL Beam uphold the structural rigidity of buildings, meeting diverse architectural demands.

Diverse Industries and Applications

SENSO LVL Timber are embraced across numerous industries, including commercial construction, interior design, furniture manufacturing, and many more. The superior quality and versatility of our products make them the first choice for various applications.

Choose SENSO LVL Timber

ROCPLY LVL Beam are a testament to our unwavering commitment to quality, performance, and sustainability. They enhance the structural integrity of commercial buildings while catering to diverse architectural needs. Discover more about SENSO range of LVL timber products, connect with our sales team, or make your purchase today – we’re ready to redefine your construction experience.

Post time: Oct-13-2025