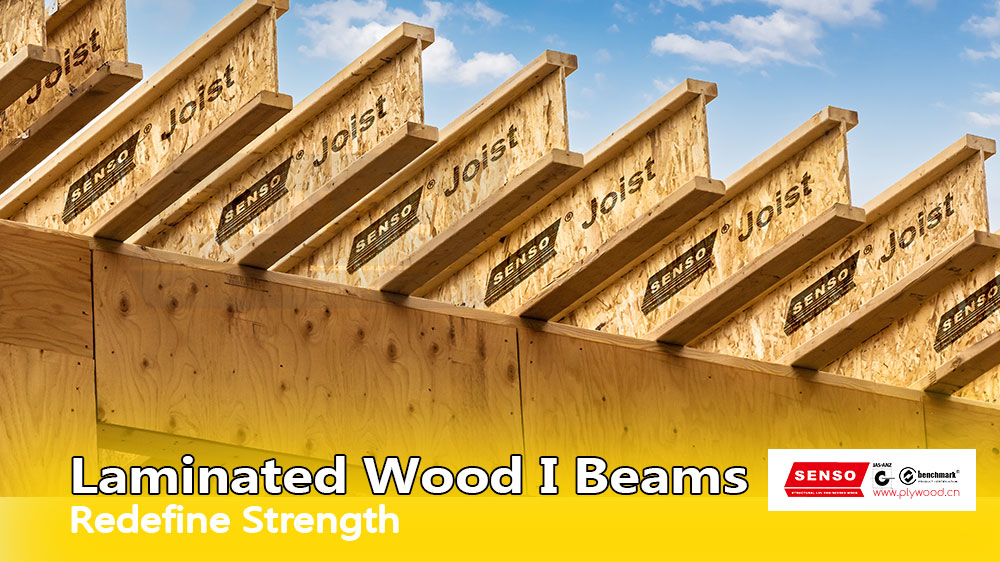

What Are Laminated Wood I Beams?

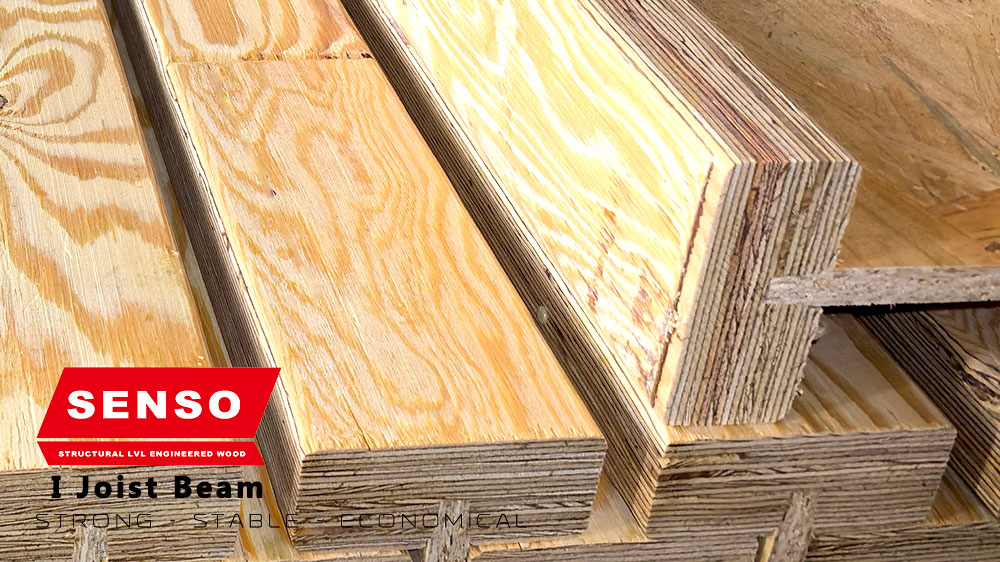

Laminated wood I beams are engineered wood components that combine strength and precision. They’re used in floor and roof framing systems. These beams consist of a strong top and bottom flange made from laminated veneer lumber (LVL) or solid sawn lumber, with a web of oriented strand board (OSB) or plywood in between. This unique “I” shape delivers high strength-to-weight performance.

Unlike traditional sawn joists, laminated wood I beams are manufactured with consistency. They resist warping, twisting, and shrinking. SENSO I Joist offers advanced versions of these beams, tailored for heavy-duty use in residential and commercial structures. Their precision and reliability set new standards for framing efficiency.

Laminated Wood I Beams: Why Builders Prefer Them

Builders prefer laminated wood I beam for good reason. They’re lighter than solid lumber and easier to handle. One person can carry and position a SENSO I Joist without machinery. This reduces installation time and labor costs.

They also provide consistent dimensions, ensuring floors are straight and level. Traditional joists often twist or bend, requiring extra adjustments. Laminated wood I beams keep structures aligned and reduce rework.

Durability is another reason to choose laminated beams. The engineered construction resists moisture and holds its shape. This makes SENSO beams ideal for long-term reliability in harsh environments.

How Laminated Wood I Beam Improve Floor Systems

SENSO I-joist laminated wood I-beams significantly improve floor performance. Because they carry loads efficiently, they allow wider spacing between supports without sacrificing strength. In turn, crews can use fewer supports and achieve more open, usable floor space.

They also reduce floor bounce and squeaks. Engineered wood floor joists are stiffer than regular lumber, creating solid, quiet floors. Builders using laminated I beams get fewer callbacks due to customer complaints.

In multi-level buildings, these beams help maintain alignment from floor to floor. Because laminated wood is more uniform, there are fewer dimensional variations between members. In turn, builders see fewer inconsistencies from one story to the next.

Comparing Laminated Wood I Beams to Traditional Wood Joists

Traditional wood joists are made from sawn lumber, so they can vary in density, moisture content, and grain. Because of these inconsistencies, floors may become uneven and structural performance can suffer. By contrast, laminated wood I-beams are engineered for uniformity, which supports straighter framing and more predictable results.

SENSO I-joist products are kiln-dried and precision manufactured. As a result, they stay true to dimension, even in extreme weather. In turn, this stability helps prevent long-term sagging and supports flatter floors over the life of the building.

Installation is also faster. Workers spend less time trimming or correcting misaligned beams. Laminated wood I beam reduce waste on-site, saving material and disposal costs.

Cost Efficiency of Laminated Wood I Beams

Though laminated wood I beam cost more per unit than solid lumber, the overall project cost is lower. Faster installation, fewer errors, and reduced labor time contribute to major savings.

SENSO I Joist beams also minimize the need for bridging or bracing. Their strength allows for longer spans. This reduces the number of pieces needed per floor and cuts back on hardware.

Over time, reduced maintenance and improved performance make these beams the smart investment. Clients appreciate smoother floors and fewer creaks, boosting satisfaction and referrals.

Environmental Advantages of Laminated Wood I Beams

Laminated wood I beams are an eco-conscious choice. SENSO uses sustainably sourced wood and minimizes waste during manufacturing. The engineered process allows better use of raw materials than traditional lumber.

These beams are lighter, reducing fuel consumption during transport. Their strength allows builders to use fewer materials overall. In green building certifications like LEED, laminated beams contribute points toward compliance.

SENSO laminated I beams also reduce job site waste. Their precision means fewer cut-offs and less scrap. It’s an environmental win from manufacturing to final installation.

Applications of Laminated Wood I Beam in Construction

Laminated wood I beam adapt well to many structural applications. They’re used for floor joists, roof rafters, and ceiling beams. Builders rely on them in residential, commercial, and industrial projects.

For residential homes, SENSO I Joist laminated beams support both single-story and multi-level structures. They carry heavier loads while maintaining shape and size. This provides homeowners with more stability and comfort.

In commercial builds, such as offices and retail spaces, laminated beams span greater distances. This reduces the need for intermediate supports, allowing for wide open layouts and flexible floor plans.

Safety and Performance of Laminated Wood I Beams

SENSO laminated wood I-beams meet or exceed relevant global safety standards. To verify performance, each beam is tested for structural load, moisture resistance, and durability. In addition, the high strength-to-weight ratio allows the beams to handle significant stress while remaining easier to lift and install on site.

These beams also perform well in seismic and high-wind areas. They bend without breaking, absorbing energy and reducing structural damage. Builders working in coastal or storm-prone regions appreciate this added security.

Fire-rated options are also available. For stricter code requirements, these beams can be treated with fire-resistant coatings. In addition, SENSO ensures its laminated wood I-beams remain code-compliant and supported by third-party certification.

Long-Term Durability of Laminated Wood I Beam

Durability defines the value of laminated wood I beam. Traditional lumber degrades over time due to moisture, pests, and temperature changes. Engineered I beams stay strong, straight, and reliable for decades.

SENSO I Joists beams use moisture-resistant adhesives and treatments. This prevents delamination, mold, and mildew in damp climates. Their resilience lowers repair and replacement costs long-term.

Clients benefit from beams that don’t shrink or swell. Floors remain flat, ceilings stay aligned, and structures last longer. SENSO products provide the kind of durability builders can depend on job after job.

What Customers Say About Laminated Wood I Beams

Contractors and developers consistently praise laminated wood I beams. They highlight faster installation times and reduced site issues. Many note how SENSO beams simplify even complex framing layouts.

One contractor stated, “SENSO I Joist beams saved us three full days on framing alone.” Another added, “They’re lighter, straighter, and stronger—my crew loves working with them.”

Wholesalers value the consistent dimensions and secure packaging. Because counts are accurate and damage rates are lower, inventory control becomes easier. In turn, project planning improves and site supply stays more predictable. For these reasons, I-joist beams continue to earn trust across global markets.

SENSO I Joist: Engineered for Precision

SENSO is a leader in laminated wood I-beam production. To deliver consistent performance, the company combines advanced technology with strict quality control. As a result, every SENSO I-joist is manufactured to tight tolerances.

In addition, our facilities use premium veneers and top-grade adhesives. With state-of-the-art pressing equipment, we achieve strong, consistent bonds between layers. Before shipment, each batch is tested for load-bearing strength and moisture resistance, so contractors receive dependable beams for demanding builds.

SENSO doesn’t just make beams—they engineer solutions. Whether supplying high-rise projects or custom homes, they tailor products to meet job-specific needs. Builders rely on SENSO for consistency, performance, and value.

Innovation in Laminated Wood I Beam

The laminated wood I-beam market continues to evolve. For example, newer designs can span longer distances while keeping weight lower. In response, SENSO supports this shift by investing in R&D and validating performance through testing of innovative core materials.

Recent improvements include stronger flange materials and more efficient webs. These reduce deflection and increase load ratings. Builders get better results with fewer beams, lowering overall costs.

SENSO also focuses on sustainability. Their latest products use lower-emission adhesives and FSC-certified wood. Future developments will further reduce carbon impact without compromising strength.

Choosing the Right Supplier for Laminated Wood I Beams

Selecting the right beam supplier impacts every project stage. Poor-quality beams cause delays, adjustments, and future failures. SENSO I-Joists products eliminate these concerns with tested reliability.

The company supports customers with global shipping, responsive lead times, and expert technical assistance. In addition, the team helps with beam selection, layout planning, and specification details. With this support in place, projects run more smoothly from planning through installation and final completion.

Builders seeking dependable laminated wood I beam trust SENSO. Their track record, innovation, and client support make them a preferred choice in structural framing.

Laminated Wood I Beams Shape the Future

Laminated wood I-beams are changing how buildings are framed. Because they are lightweight, durable, and dimensionally precise, they match modern demands for efficiency and performance. From residential homes to high-rise offices, these beams often outperform traditional framing members in consistency and installation speed.

SENSO I Joist beams stand out for their quality, support, and environmental responsibility. Builders who switch to laminated I beams never go back. Their value becomes clear from the first installation.

If you’re looking for strength, speed, and stability, laminated wood I beams are the answer. And when it comes to reliable supply and engineered excellence, SENSO leads the way.

Post time: May-01-2025