Every frame starts with a stud choice. That choice shapes how walls look, feel and perform for years. If laminated veneer studs twist or bow, the problem shows through plasterboard, tiles and joinery.

In markets like Australia, MGP 10 pine framing remains the usual starting point. It gives a cost effective grade for many standard house frames. MGP 12 structural pine steps in when loads rise or walls grow taller.

Design trends keep pushing these grades harder. Higher ceilings, long tiled bathrooms and full height cabinets now appear even in entry level homes. Those features demand straighter, stiffer stud walls. Laminated Veneer Studs answer that demand with engineered stability and tight control of line.

SENSO positions its Laminated Veneer Studs as a practical upgrade, not a total system change. Crews still frame in a familiar way, but the frame behaves more predictably.

What Laminated Veneer Studs actually are

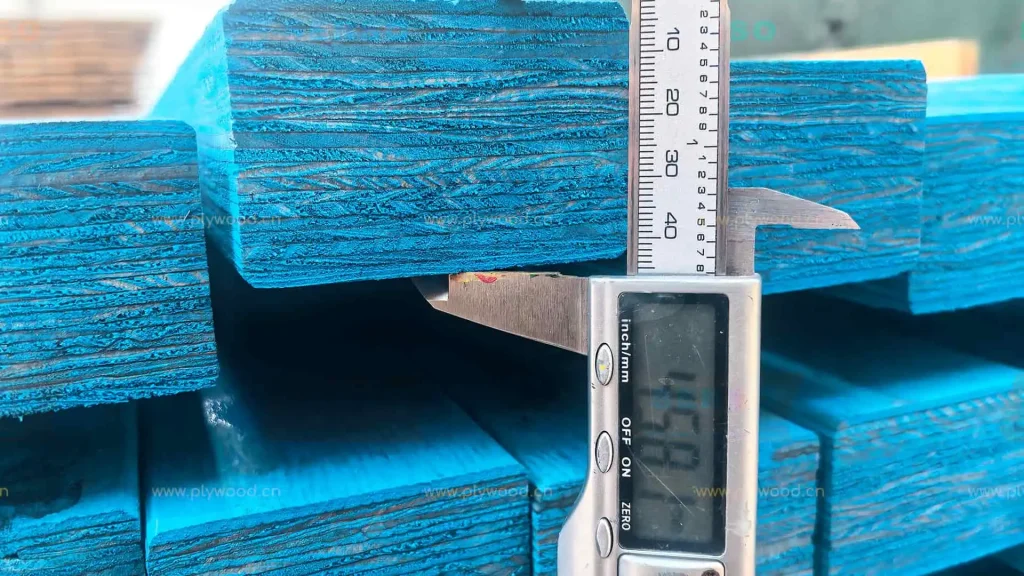

Laminated Veneer Studs belong to the laminated veneer lumber family. Thin veneers peel from selected logs, then dry under controlled conditions. The dry layers glue together under heat and pressure, with grains running in one direction.

This layup creates a dense, uniform section. Natural defects such as knots spread through many veneers and lose impact. The result is a stud with consistent strength and stiffness along its full length. That consistency sets LVL studs apart from solid pine, where each piece reflects one unique log.

SENSO Laminated Veneer Studs build on this base. We focus on line control, moisture management and clean machining. Our LVL studs arrive straight, dimensionally accurate and ready for normal tools. Crews cut, nail and drill them just like pine, so adoption stays smooth on busy sites.

Because laminated veneer lumber starts dry and stable, it tends to move less in service. Walls stay closer to line from slab pour through to final paint.

How MGP 10 pine framing fits into the picture

MGP10 pine framing still dominates many stud racks. Machine grading sorts pieces into a stress grade with target strength and stiffness. The grade suits walls, roof frames and many general structural tasks.

It offers a strong balance of cost, performance and availability. Pine grows quickly in plantations, so supply remains broad and volumes stay high. Builders like MGP 10 because it feels familiar. It cuts easily, nails quickly and suits standard details.

Yet the material still behaves like solid wood. Each stud comes from one log with its own grain and knot pattern. Even within one stress grade, variation in stiffness and movement remains.

On simple, low walls with forgiving finishes, that variation rarely causes trouble. On tall, feature or tiled walls, small changes in stud line can become very obvious. That is where many teams now step up to engineered wall studs for key zones.

MGP 12 structural pine and its role

MGP 12 structural pine takes the same idea one step further. It offers higher strength and stiffness values than MGP 10. This extra capacity helps in heavier roofs, larger spans and wind sensitive sites.

Merchants often stock MGP 12 in core framing sizes. Designers call for it in selected walls, upper floors or other critical areas. It gives a neat middle step between MGP 10 pine framing and full LVL systems. Crews still handle it with the same tools and fixings.

However, MGP 12 remains a solid timber product. Natural variation within the grade band still exists. Moisture changes can still cause twist, bow and local movement. In many projects, those movements matter as much as strength. Tiles, cabinets and long plasterboard joints all respond to tiny shifts in line.

Laminated Veneer Studs tackle this weak point directly. They deliver a structural level comparable with higher pine grades, yet they keep shape much more reliably.

Laminated Veneer Studs vs MGP10 vs MGP12

| Aspect | Laminated Veneer Studs | MGP10 pine framing | MGP12 structural pine |

| Product type | Engineered laminated veneer lumber | Solid plantation pine | Solid plantation pine |

| Structural level | High, tight performance band | Base residential grade | Higher strength residential grade |

| Straightness | Very straight, minimal twist and bow | Can twist or bow, more sorting | Improved, still natural variation |

| Moisture behaviour | Starts dry, stable response | More movement with climate change | Similar movement to MGP10 |

| Best fit | Tall walls, tiles, feature zones | Standard, cost driven frames | Heavier loads, selected key walls |

| Typical treatment | H2 / H2S as required | H2, H2F, H3 widely used | H2, H2F commonly used |

Laminated Veneer Studs vs MGP 10 and MGP 12 at a glance

The comparison between Laminated Veneer Studs and pine framing comes down to behaviour as much as strength. MGP 10 and MGP 12 offer proven performance but follow natural patterns. Laminated Veneer Studs behave like a precision component.

Sales teams often use a simple table to explain the difference. They highlight product type, structural level, straightness, moisture behaviour and best fit. In each row, Laminated Veneer Studs stand out for consistency and line control.

This quick view helps wholesalers position SENSO Laminated Veneer Studs as the premium stud choice. It also gives builders a clear reason to reserve the LVL option for high impact or high risk walls.

Straightness, finish quality and fewer call backs

Straight walls help every trade. When studs line up, plasterboard joints stay flat and easy to finish. Tiles sit with less lippage, even in long bathrooms and showers. Cabinets and wardrobes need fewer packers behind the carcass.

Laminated Veneer Studs make that straightness easier to achieve. The engineered layup resists bow, crook and twist. The studs start dry and stay stable in normal indoor framing conditions. Crews see fewer rogue pieces that refuse to sit on line.

With MGP 10 pine framing, good results are still possible. Carpenters simply work harder to sort and straighten. They push poor sticks into short studs or blocking. They spend added time pulling frames back into plumb before bracing. MGP 12 structural pine behaves slightly better, yet the same patterns still appear on many jobs.

SENSO Laminated Veneer Studs reduce that hidden labour. Frames stand faster. Walls need fewer packers. Trades downstream notice that backgrounds feel flatter and more solid. Over time, that smoother process means fewer call backs for cracked tiles, binding doors or wavy hallways.

Cost, waste and real installed price

At first glance, Laminated Veneer Studs usually cost more per metre than pine. MGP10 often sits lowest on the price sheet. MGP 12 sits in the middle, and the LVL stud price appears at the top. On paper, pine seems cheaper.

Real projects tell a different story. Installed cost depends on waste, labour and rework, not just material price. Packs of engineered wall studs tend to hold very few rejects. Most lengths go straight into the frame. With pine, more sticks turn into short off cuts or skip waste. Disposal fees and truck movements follow that waste.

Labour also shifts the equation. Time spent sorting, swapping and straightening studs adds up quickly. LVL studs help crews stay in a smooth rhythm. They stand walls, fix them off and move to the next area. Downstream trades also speed up because surfaces stay flatter.

Rework often costs the most. Call backs for cracks, doors that bind or bowed feature walls eat into margin and goodwill. Laminated Veneer Studs reduce those risks by holding line and stiffness over time. For many builders, that reduced rework offsets the initial price gap on the very first project.

Durability, treatment and moisture control

Durability for indoor framing usually rests on two things. First, termite protection must suit the local risk level. Second, the frame must handle normal moisture changes without distress.

MGP10 pine framing and MGP 12 structural pine both come in H2 or H2F termite treatments for indoor, above ground use. They can also appear in H3 for some outdoor, above ground tasks. These systems have a long track record and fit standard details.

Laminated veneer lumber can match that protection. Glue line and surface treatments reach through the section, so LVL studs can meet the same hazard classes. SENSO Laminated Veneer Studs follow this approach, which keeps specification simple for designers.

Moisture movement behaves differently. Solid pine shrinks and swells with seasonal changes. Uneven drying can cause twist, bow and gaps at joints. LVL studs start at a low, uniform moisture content. The bonded veneers help each section respond in a more even way. Over time, that stability supports tight joints and neat finishes across the wall surface.

Design freedom with Laminated Veneer Studs

Architects and owners now ask for taller walls, stacked glazing and wide openings. These features look great, but they load studs more heavily. They expose any deflection or misalignment under strong light.

Engineered wall studs handle these demands well. Products like SENSO Laminated Veneer Studs offer high stiffness and strength for their size. They suit tall walls, window jambs, stair voids and cabinet walls where movement must stay very small.

Timber wall framing still feels the same on site. Carpenters simply swap some pine studs for LVL studs in critical areas. Engineers gain clearer data and tighter performance bands from the LVL design guides. They can specify stud layouts with more confidence, and often with fewer awkward stud clusters at wide openings.

SENSO Laminated Veneer Studs also pair naturally with LVL beams and other engineered timber framing elements. The whole frame behaves as one integrated system, with predictable load paths and consistent deflection control.

When pine still suits the job

Pine continues to play an important role. Not every wall needs premium performance. Many low, internal partitions carry light loads and see gentle finishes. In these areas, MGP10 pine framing remains a sensible and economical choice.

MGP 12 structural pine also keeps value where loads rise but design stays simple. It gives extra strength without changing basic site practice. Some builders and customers prefer to stay with solid timber for familiar, budget sensitive projects.

A smart mix often works best. Internal non critical walls can stay in pine. High impact zones, such as tiled bathrooms, kitchen walls, long corridors and feature façades, step up to Laminated Veneer Studs. This blend balances cost and performance across the frame.

Choosing SENSO Laminated Veneer Studs as the upgrade

Wholesalers need framing ranges that make sense at the counter. One simple ladder works well. MGP10 serves the entry level. MGP12 offers the mid tier. SENSO Laminated Veneer Studs take the premium step for demanding walls.

This structure gives sales staff a clear story. They can match stud choice to ceiling height, finish type and client expectations with a few quick questions. The range protects margin and stops good customers leaving to find engineered wall studs elsewhere.

Builders gain a practical upgrade that fits their current framing style. They keep timber wall framing, nail guns and plates. They simply choose SENSO Laminated Veneer Studs where performance really matters. Over time, they see straighter walls, calmer sites and fewer after sales problems.

In the end, Laminated Veneer Studs do not fight pine. They work alongside it. Pine covers simple spans and modest finishes. SENSO Laminated Veneer Studs protect the walls that carry high loads, premium tiles and long cabinet runs. Together, they create a flexible framing system that suits modern design, tight programs and rising client expectations.

Post time: Feb-09-2026