Laminated Veneer Stud vs pine framing MGP10 and MGP12

Frames once looked simple. Most houses used pine framing with laminated veneer stud and MGP10 timber in almost every stud. Some higher walls shifted to MGP12 pine, but the general approach stayed the same. Designs then changed. Walls grew taller, openings widened, and finishes grew far more demanding.

Small twists in a stud that once hid behind plasterboard now stand out. Tiles crack, cabinet lines wander, and owners notice every ripple in the paint. Builders feel these problems in warranty costs and stress. Those issues led many crews to try LVL studs and, later, full LVL wall framing. Laminated Veneer Stud products now sit at the centre of that shift.

Why engineered Laminated Veneer Stud framing is gaining attention

Several forces push the market toward engineered wall studs. High ceilings and big open living areas increase wall height and load. Feature windows and sliding doors need straight, stiff frames around them. Natural wall studs still work, but they often sit near their safe limits.

Finishes changed just as quickly. Many buyers now choose full height bathroom tiles, long stone splashbacks, and large format boards. These finishes leave very little room for movement behind them. Even tiny stud movement can crack grout, open sealant, or show as shadow lines. Laminated veneer wall framing cuts that movement and holds walls in line.

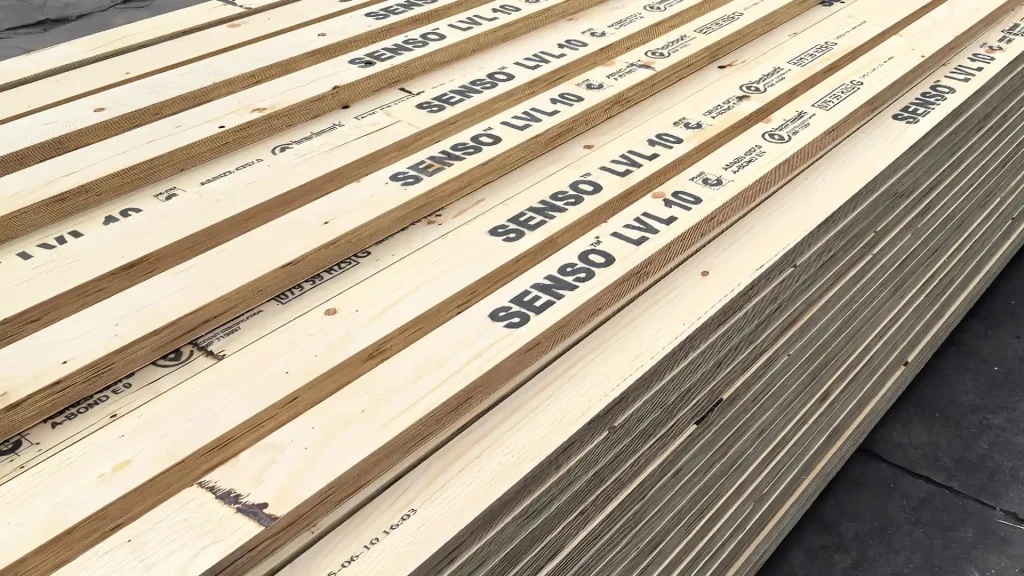

Labour pressure adds another push. Carpenters do not have time to sort piles of curved wall studs. They want packs that deliver high yield and steady behaviour. SENSO Laminated Veneer Stud answers that need. Members arrive straight, keep their line, and help crews frame faster.

How Laminated Veneer Stud compares with MGP10 timber and MGP12 pine

MGP10 timber and MGP12 pine both come from solid boards. Each board follows the grain of a single tree. Grading measures stiffness and assigns a strength grade, yet natural variation remains. Moisture changes still bring bow, twist, and cup to many wall studs.

A LVL Stud starts from thin veneers. All veneers run along the stud length. SENSO bonds them under heat and pressure to form LVL studs. This build spreads knots and growth features through many layers. The result is a stud with predictable strength and stiffness.

The table below sets out the main differences.

| Property | Laminated Veneer Stud | MGP10 timber | MGP12 pine |

| Base material | LVL studs, many thin veneers | Solid softwood board | Solid softwood board |

| Strength variation | Low, engineered and controlled | Higher, piece to piece | Moderate, better than MGP10 |

| Straightness in pack | Very straight and consistent | Varies by pack | More consistent, still variable |

| Moisture movement | Lower when detailed correctly | Strong response to wet and dry | Similar to MGP10, sometimes lower |

| Best use | Tall, tiled, feature walls | Simple internal walls | Taller walls where budgets are tight |

On site issues with wall studs and pine framing

Design tables tell only part of the story. Real sites add rain, mud, and tight inspection times. Ladders lean against frames, and stacked materials press on walls. Under those conditions, stud stability becomes critical.

Traditional pine framing often needs heavy sorting. Crews reject curved wall studs or cut short studs from better sections. They then fight small bows while they stand and brace walls. The frame may leave the slab straight, but movement later can still appear during lining.

Laminated Veneer Stud products behave differently. Packs from SENSO contain a high share of straight, ready to use studs. Crews spend more time fixing and less time sorting. Long corridor walls hold their line. Window and door openings stay square with less force.

This behaviour helps finish trades as well. Plasterboard, fibre cement, and cladding sit flatter on LVL studs. Nail lines land near the centre of each member. Joint cracking in corners and at ceiling lines reduces. That outcome saves time and lifts finish quality.

Cost view of Laminated Veneer Stud and pine framing

Price per metre still matters. MGP10 timber usually sits at the entry point. MGP12 pine costs more and often fills a mid range role. Laminated Veneer Stud products from SENSO sit above both grades in pure price.

Total cost tells a richer story. Frames consume labour, not just material. Bent or twisted wall studs add hidden hours. Carpenters sort, straighten, and sometimes replace poor pieces. After lining, call backs for cracks or stuck doors eat more time.

A simple cost view looks like this.

| Cost factor | Laminated Veneer Stud | Pine framing (MGP10 / MGP12) |

| Price per linear metre | Higher | Lower |

| Sorting and waste | Low waste, high usable yield | More waste on long lengths |

| Labour during framing | Faster, fewer corrections | Slower, more straightening |

| Risk of finish defects | Lower in key rooms | Higher with hard, brittle finishes |

| Overall value in complex builds | Strong | Variable, depends on detailing |

Design flexibility with LVL studs and wall systems

Engineers like flexible tools. Laminated Veneer Stud sections give that flexibility. Higher stiffness allows taller walls, wider bracing panels, and more ambitious openings. Frames can support larger windows and stacked doors while staying within deflection limits.

LVL studs also work well with structural LVL beams and LVL wall framing. Using one material family simplifies design values. Loads move through wall studs, beams, and lintels with clear, consistent rules. This structure makes it easier to design bracing walls, portal frames, and feature entries.

Pine framing still sits in the toolbox. Many designers keep MGP10 timber or MGP12 pine for simple, non structural partitions. They then specify SENSO LVL Stud in high risk or high value walls. That mix keeps budgets controlled and performance high.

Moisture, climate and Laminated Veneer Stud stability

Weather and climate push frames hard. Walls stand open during early stages. Rain hits plates and wall studs. Later, heating and cooling drive new changes. Natural timber shrinks and swells as these cycles pass.

LVL studs respond in a more controlled way. SENSO dries veneers to tight ranges before pressing. Glue lines then lock that structure in place. When builders store and detail LVL Stud framing correctly, movement stays low.

This stability helps in wet and hot regions. External walls face sun, wind, and storm rain. Laminated Veneer Stud products limit warping between ties and nogs. Cladding and linings enjoy a more stable base. Paint, sealant, and flashing details then perform better over time.

Where Laminated Veneer Stud adds the most value

Not every wall needs an engineered stud. Some rooms clearly benefit, though. Bathrooms and laundries with full height tiles sit at the top of the list. Small movements behind tiles can crack grout or open joints. Laminated Veneer Stud framing helps keep those walls flat and firm.

Kitchens come next. Heavy wall cabinets, rangehoods, and stone splashbacks all prefer stiff, strong wall studs. LVL studs support those loads and keep lines straight. Tall living and entry walls with large glass areas also gain from engineered framing. These walls show every deviation to the eye.

External walls in high wind zones form another key group. SENSO Laminated Veneer Stud products help resist both short term wind load and long term creep. Clients enjoy quieter, more solid homes. Builders enjoy fewer warranty calls.

Internal bedroom walls with simple paint do not always need LVL studs. MGP10 timber or MGP12 pine can still serve well there. Smart builders map their frames and place Laminated Veneer Stud members where they earn their keep.

People also ask about LVL wall framing

Is a LVL stud stronger than a pine stud? Engineered LVL studs usually offer higher and more reliable stiffness than standard MGP10 timber. They often match or exceed MGP12 pine in strength, depending on grade and size.

Can I mix LVL studs and pine studs in one frame? Many builders already do this. They place Laminated Veneer Stud products in bathrooms, kitchens, tall walls, and high wind areas. They use pine framing in low risk internal walls.

Do LVL studs need special tools or fixings? No special tools are needed. SENSO LVL stud members cut and fix with normal saws and nail guns. Crews simply follow the nailing and edge distance rules in the guide.

Will LVL studs stop plaster cracks completely? No framing system can remove every crack risk. LVL Stud framing reduces movement behind the lining. Good jointing, fixing, and control of moisture must still support the frame.

SENSO LVL solutions for wholesalers and builders

Wholesalers and large builders need more than a clever product label. They need stable supply, clear data, and a clean story for their customers. SENSO Laminated Veneer Stud fits that need.

For wholesalers, these LVL studs create a premium tier above pine framing. Sales teams can offer three steps. Standard MGP10 timber for basic internal stud walls. MGP12 pine for some taller or heavier walls. Laminated Veneer Stud framing from SENSO for feature spaces and high value rooms.

For builders, the change feels calm. Crews keep current tools and general details. They start by using SENSO Laminated Veneer Stud in one or two key zones. Over time, many expand use as they see fewer problems and smoother handovers.

In the end, Laminated Veneer Stud products let pine framing do what it does best. LVL studs then take over where risk and client expectations stand higher. That balance keeps frames efficient, finishes sharp, and reputations strong.

Post time: Jan-30-2026