Why Stud LVL wall framing is gaining attention

Stud LVL wall framing now sits beside pine in many racks. Builders still trust MGP10 pine framing for standard walls and use MGP12 pine framing when loads rise. However, they also feel the limits of solid timber, including movement, twist, and added sorting cost.

SENSO Stud LVL wall framing offers a different balance. It keeps familiar timber handling yet adds engineered stability. Veneers lay in a controlled pattern, so stiffness stays consistent along each length. LVL wall studs then behave in a more predictable way than most solid pieces.

As design trends move toward higher ceilings and long runs of wall, this consistency matters more. Indoor comfort, straight corners, and neat joints all start inside the stud frame. When the frame improves, almost every trade downstream gains time and confidence.

Stud LVL wall framing and pine grades at a glance

At a simple level, MGP10 pine framing remains the entry point for many house frames. It suits single storey homes and light internal walls. MGP12 pine framing steps up for heavier walls, key bracing zones, and some roof or floor applications.

SENSO Stud LVL wall framing aims at the same core framing space. It offers LVL wall studs that can serve as an alternative to MGP10 and a design substitute for MGP12 in many cases, always subject to engineering checks and local standards.

The key difference lies in variation. Pine grades group pieces by average performance. Some sticks sit above the line, others below. LVL framing timber tightens that band. Engineered wood framing delivers more pieces near the design values, with fewer weak links in critical wall zones.

Strength and stiffness in wall studs

Strength ratings guide structural design, yet stiffness often decides how a wall feels in daily use. Soft spots in a frame can cause cracks, rattles, and small movements that owners notice quickly.

MGP10 pine framing gives adequate strength for many domestic applications. It meets the minimum structural level for many wall types. MGP12 pine framing increases stiffness and strength, so it suits higher loads and some taller frames.

Stud LVL wall framing approaches this from another direction. LVL wall studs use oriented veneers, so grain runs along the member and defects scatter. This configuration produces high stiffness with less scatter. Designers then model wall deflection with more confidence, especially in tall walls or narrow panels between large openings.

In real projects, that means fewer surprises. A corridor wall feels solid from end to end. Feature walls near large windows remain stable as wind loads shift. Doors and windows stay aligned longer, even as seasons change.

Straightness, finish quality, and rework on site

Straightness on site has huge impact. A pack of bent wall studs can slow a crew for hours. Carpenters then start packing plates, shaving edges, and culling pieces that twist too far. Each fix drains time and energy.

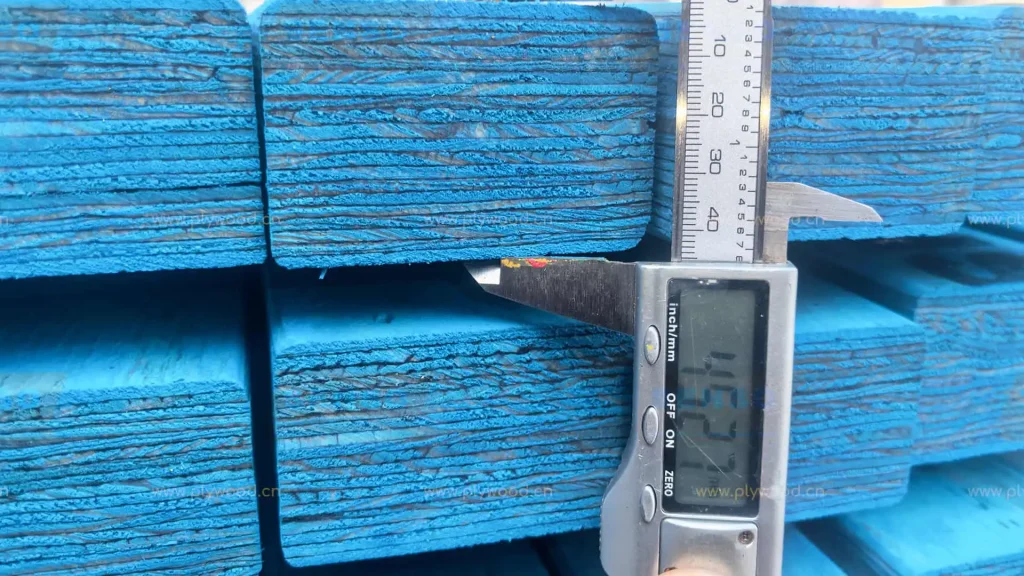

With SENSO Stud LVL wall framing, the LVL wall studs arrive straight and tend to stay that way. The laminated structure resists bowing and twisting as moisture levels change. When crews stand walls, they see clean lines with less effort. Lasers track true, and gauges reveal fewer gaps.

This stability flows through to finish trades. Plasterboard teams need fewer packers and back blocks. Tiles meet flatter bathroom walls and shower recesses. Kitchen fitters deal with straight reveals and strong screw lines. Painters then face fewer hairline cracks from frame movement.

Pine frames can deliver good results when drying, handling, and storage all stay tight. Yet variation within and between packs makes life harder. Just one poor pack of studs can drag down a week of work. Stud LVL wall framing reduces that risk and gives teams more predictable days.

Labour, speed, and total cost

Many price talks start with timber rates per metre, but labour and rework usually decide actual project cost. Every extra hour spent fixing a frame eats into margin and stretches timelines.

When crews use Stud LVL wall framing, they usually see shorter set out times. Studs come from the pack, go into the wall, and stay there. Sorting shrinks, and cutting for defects drops. As a result, frames stand faster, with fewer minor adjustments.

Using MGP10 pine framing often involves more screening. Carpenters sight along each stick and decide if it suits full height use. MGP12 pine framing behaves better, yet still shows points of natural weakness. Off-cuts and reject piles grow over the day and represent lost value.

When you include labour, waste, prelims, and call backs, Stud LVL wall framing often closes the initial price gap. The framing rack that first looked more expensive can actually protect the budget once the last painter leaves the site.

Stud LVL wall framing vs pine framing

| Feature | SENSO Stud LVL wall framing | MGP10 pine framing | MGP12 pine framing |

| Material type | Engineered LVL wall studs | Solid pine, machine graded | Solid pine, higher grade |

| Straightness | Very straight and stable | Variable, more sorting needed | Better than MGP10, still variable |

| Typical use | Tall walls, feature walls, mid-rise panels | Standard internal and external walls | Higher load walls, some roofs |

| Labour impact | Faster set out, less rework | More time packing and trimming | Less rework than MGP10, more than LVL |

| Durability & moisture | Good stability through wet/dry cycles | Can cup or twist if poorly managed | Similar moisture risk to MGP10 |

| Termite treatment | Integrated LVL treatment options | H2 / H2S options | H2 / H2S options |

Stud LVL wall framing in taller and mid-rise projects

As markets push toward taller timber structures, wall stud performance matters more. Mid-rise residential projects often use light weight stud framing for speed and weight savings. In these jobs, wall height, opening size, and bracing all demand careful control.

Stud LVL wall framing suits this environment. LVL wall studs carry high stiffness values and maintain those values with less spread. Engineers can design to tight serviceability limits for drift and deflection, knowing that actual members will track design data closely.

By comparison, MGP10 pine framing may reach its comfort zone sooner in tall walls. Designers often step up to MGP12 pine framing or add more studs and blocking. That path works but adds material and labour. LVL framing timber often offers a cleaner solution with stable properties.

In mid-rise projects, small movements can create large visual effects. Cracks along long corridors, stiff corners near lifts, and acoustic gaps all tie back to frame behaviour. Stud LVL wall framing helps limit these issues and keeps clients happy during long defect periods.

Durability, termites, and moisture

Durability includes termites, rot, and weather. Framing products must manage these risks over decades, and treatment class, moisture management, and detailing all play important roles.

MGP10 pine framing and MGP12 pine framing often appear with H2 or H2S termite treatment for internal, above ground use. This approach works well when trades follow cutting and sealing rules, yet deep cuts or unsealed ends can still expose cores.

Stud LVL wall framing can use integrated treatment systems. Treatment moves into veneers and glue lines during manufacture. This approach protects more of the cross section, even after drilling or modest trimming. For wall studs, that depth of protection reduces the chance of hidden weak points.

Moisture cycles also affect wall framing. Solid pine may cup, bow, or twist after heavy rain and fast drying on exposed frames. LVL sections, including LVL wall studs, generally move less. Frames then stay closer to line between slab pour, frame stage, and lock up.

Off-site panels and prefabrication with Stud LVL wall framing

Off-site framing plants and panel factories depend on repeatability. They use jigs, saw lines, and nail plates at high speed. Any material that behaves unpredictably slows the whole system.

Stud LVL wall framing supports this model. LVL wall studs arrive in tight length and moisture ranges. Their straightness suits automated feeds and clamping systems. Panel sizes remain accurate, so installers on site spend less time forcing modules into line.

Pine framing still plays a role in many plants, especially for cost driven projects. Yet any saving in purchase price can vanish through extra rejects, adjustments, and call backs. Many panel lines therefore shift key walls to LVL framing timber first and increase LVL share over time.

For SENSO partners, this creates a clear story. SENSO Stud LVL wall framing provides the stud backbone, while structural LVL beams and lintels round out the system. Plants can then promote a full engineered wood framing package built around one consistent brand.

Where MGP10 and MGP12 still fit

Pine will not disappear from framing racks. Both MGP10 pine framing and MGP12 pine framing still suit many wall types. Short internal partitions, minor renovations, and highly price sensitive work often do not require engineered studs.

MGP12 pine framing also keeps a strong role in roof systems, selected bracing walls, and legacy details. Engineers and builders know those patterns well and may choose to keep them in place while they trial Stud LVL wall framing in other zones.

A balanced strategy often works best. Builders might use Stud wall framing for tall walls, long corridors, and key bracing lines. They then keep pine for simple, low risk partitions. This mix improves overall performance without shocking budgets or forcing crews to change every habit at once.

How SENSO Stud LVL wall framing supports wholesalers and frame plants

Wholesalers and frame plants need more than product. They need security around quality, supply, and technical support. Frames that fail or move too much damage both profit and reputation.

SENSO Stud LVL wall framing slots into this picture as a dependable option. It offers LVL wall studs that function as a premium alternative to MGP10 and as a design substitute for MGP12 in many situations, subject to approval by the project engineer. Because performance remains consistent, claims stay rare and margins stay protected.

SENSO also backs partners with technical data, span guidance, and training support. Sales teams learn to compare LVL and pine in plain language. They can talk about straightness, labour savings, and wall quality rather than only metre rates. Marketing tools, such as brochures and web copy, then help explain the Stud LVL wall frame story to builders and designers.

Frame plants gain a clear platform, too. By pairing Stud LVL wall framing with matching structural LVL beams, they build complete engineered solutions. These packages stand out in tenders and support long term relationships with builders who need predictable performance.

FAQs about Stud LVL wall framing and pine framing

Many builders and buyers share the same first questions. Clear answers help them choose the right framing mix for their work.

One common question asks whether Stud LVL wall framing is stronger than MGP10 pine framing. In many cases, LVL wall studs offer higher and more consistent stiffness than typical MGP10 pine framing, which improves tall wall behaviour.

Another question centres on cost. LVL studs often cost more per metre than pine, yet that is not the whole story. When straighter frames reduce labour, waste, and call backs, total project cost can fall or at least stay steady.

Compatibility also matters. The LVL stud range fits standard timber framing practice. It works with familiar sizes, plates, and connectors, always within the guidance of project engineers. Frame plants can feed the product into existing lines with limited changes.

In the end, Stud LVL wall framing comes down to trust and outcomes. Builders need to trust each stud they lift into place. Wholesalers need to trust the company that stamps each length. With SENSO Stud LVL wall framing, both groups gain a dependable partner that supports straight walls, neat finishes, and steady profits, project after project.

Related SENSO LVL resources

- SENSO LVL 10 studs specifications, sizes, and packing

- How engineered studs upgrade standard timber framing

- LVL and pine wall framing guide for builders and merchants

- LVL timber overview for construction and framing

- LVL wall studs articles and use cases

- Frame LVL beam range for structural applications

References

Post time: Jan-14-2026