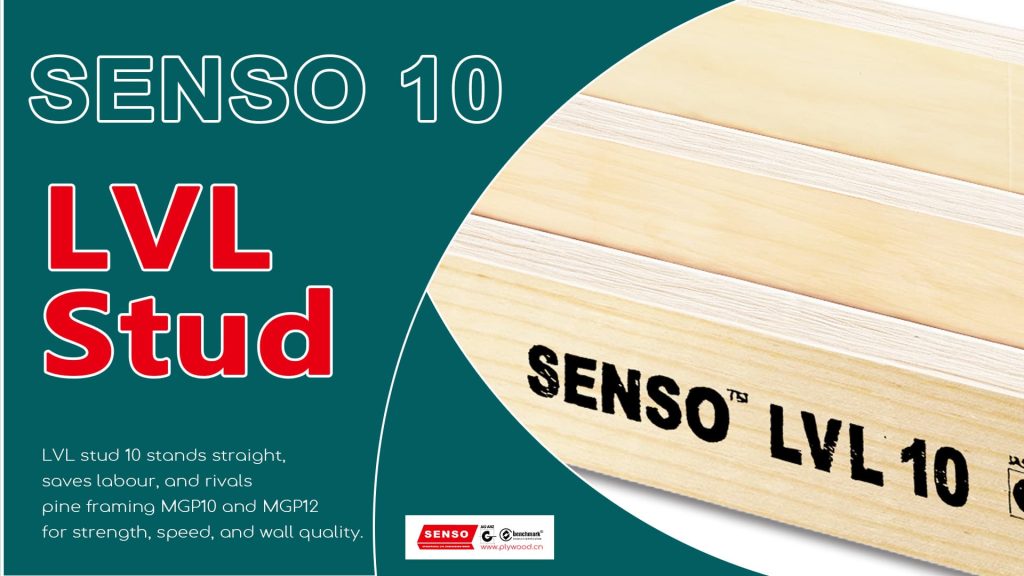

LVL stud 10 vs Pine Framing MGP10 and MGP12 – SENSO LVL Stud Guide

Builders and wholesalers keep comparing stud options in LVL and pine framing every day. SENSO LVL stud 10 gives straighter walls, fewer call-backs, and easier lining work. The engineered timber section stays stable in heat or moisture, so crews spend less time wrestling twisted pine. For busy sites that run tight schedules, engineered studs and LVL framing timber help reduce waste and speed up fixing. With strong support from SENSO on stock planning and technical data, your framing jobs stay predictable, profitable, and calm. That means happier crews and fewer warranty headaches.

Why builders shift to LVL stud framing

Across many sites, the wall frame sets the tone for the whole build. Crooked studs slow everything down.

Traditional pine framing MGP10 and MGP12 still dominates many yards. It feels familiar and cheap.

Yet more supervisors now ask for an LVL wall framing solution instead. They want straight walls on day one.

They also want those walls to stay straight after plasterboard, tiles, and joinery go in.

LVL wall framing answers that need with engineered stability and reliable strength.

SENSO LVL stud 10 steps into this space as a simple swap.

It fits common stud sizes and suits the same wall layouts. However, it behaves like a higher class product on site.

How SENSO LVL stud 10 compares on strength and stiffness

Pine framing MGP10 and MGP12 use solid timber with natural variation between sticks.

An LVL wall member uses many veneers in a laminated veneer lumber layup.

Each veneer lines with the grain and bonds under high pressure for consistent performance.

SENSO LVL stud 10 targets the same general duty range as MGP10 framing yet offers steady stiffness along each length.

Compared with MGP12, LVL keeps more of its stiffness after repeated wetting and drying cycles.

This matters where walls sit over damp slabs or open frames for weeks before close-in.

In practice, many builders use engineered studs for key load lines and keep MGP10 pine for simple internal walls.

This mix keeps budgets under control while lifting performance where it counts most.

Wall straightness and finish quality with SENSO LVL framing

Strength numbers matter on drawings, yet straightness often matters more on site.

Twisting studs slow crews, and one bad pack of pine can blow out hours on a frame.

Engineered LVL framing stays far more stable than solid pine as moisture changes.

SENSO LVL stud 10 arrives straight and stays straight for faster wall set-out.

Crews line walls faster, because every piece behaves the same and laser lines stay tight.

Plasterboard fixes with fewer packers and back blocks, and finish trades see flatter walls.

For the builder, that means fewer call backs and smoother handovers.

For wholesalers, it means loyal customers who return for repeat engineered stud orders.

Speed, labour, and site cost differences

Time on site now costs more than timber, and labour rates climb.

LVL framing helps cut wasted time because straight members reduce checking and re-work.

Crews trust SENSO LVL stud 10, pull from the pack, stand the wall, and fix without heavy sorting.

MGP10 pine framing and MGP12 pine framing still need more sorting on many jobs.

Twisted or bowed lengths often end in a reject pile that still costs money.

SENSO LVL framing suits pre-cut and pre-nailed frame plants with automated lines.

Consistent density and stiffness help those lines hold tight tolerances for faster installs on site.

Project managers feel this as fewer delays and lower warranty calls over a full program of work.

Span, height, and design flexibility for modern layouts

Modern homes keep growing taller and more open with long corridors and high ceilings.

The choice between LVL studs and pine framing affects those layouts and span options.

Because an LVL wall member carries predictable stiffness, engineers can push height further.

They gain confidence in deflection control and serviceability in tall walls.

MGP 10 pine framing sets basic limits for many standard designs in volume housing.

To reach higher walls, designers often jump to MGP12 or add more studs and cost.

SENSO LVL stud 10 opens other options and supports slimmer walls in some cases, subject to design checks.

This flexibility supports off site construction and panel plants that want one engineered specification.

Termite treatment and durability in pine framing and LVL

In many regions, termite risk drives framing choice and treatment class.

Pine framing MGP10 and pine framing MGP12 often receive H2 or H2S treatment for internal use.

LVL framing can carry similar or improved termite protection embedded in the veneers.

SENSO LVL stud 10 follows this thinking with treatment integrated in the production process.

Even if carpenters notch or rebate a stud, the treated zone still protects the core.

Durability links to moisture resistance as well as termite resistance.

Solid pine may cup or twist after soaking rain and rapid drying cycles.

LVL performs better under these cycles thanks to its laminated cross section design.

Supply, grading, and quality control for framing products

Supply chains for framing timber feel constant pressure from weather and mill changes.

Grades like MGP 10 and MGP 12 can tighten without much warning in some regions.

LVL production works differently and mills peel veneers from logs before grading each sheet.

This approach allows manufacturers to control quality across large volumes more easily.

SENSO builds stud LVL 10 on modern lines with strict process control and mechanical checks.

For wholesalers, this stable process means predictable stock and tight length tolerances.

Packs arrive with consistent moisture content so inventory turns faster and claims drop.

LVL stud 10 vs pine framing

| Feature | SENSO LVL stud 10 | Pine framing MGP10 | Pine framing MGP12 |

| Material type | Engineered laminated veneer lumber | Solid pine, machine graded | Solid pine, higher grade |

| Straightness on site | Very straight and stable | Variable, needs sorting | Better than MGP10, still variable |

| Typical use | Key load walls, tall frames, offsite panels | Standard internal and external walls | Higher load walls and trusses |

| Labour impact | Faster set-out, less re-work | More checking and packing | More checking than LVL |

| Termite treatment | Integrated LVL treatment options | H2 / H2S treatment options | H2 / H2S treatment options |

When pine framing MGP 10 still suits the job

MGP10 pine framing still suits many applications and will not vanish from yards.

Short walls, non-structural partitions, and simple renovation jobs often use standard pine.

Price-sensitive projects may favour MGP10 where budgets sit under heavy stress.

Builders may choose pine for internal walls and reserve LVL wall framing for key bracing lines.

MGP12 steps in where higher strength is needed yet design demands remain simple.

SENSO does not ask builders to abandon pine framing in their business.

Instead, SENSO LVL stud 10 complements existing options as a higher performance choice.

How wholesalers profit with SENSO LVL stud packages

Stocking a new stud system only makes sense when numbers work for the yard.

With SENSO stud LVL 10, yards gain a clear upgrade story for builders.

Sales teams can explain straighter walls, fewer call backs, and happier crews in simple language.

They can then price the LVL stud as a premium yet fair step above MGP 10 pine.

Because the product performs consistently, claims and returns stay low and protect margin.

Frame plants and larger builders often sign supply agreements for LVL framing packages.

SENSO backs this with technical data, span guides, and joint marketing materials.

The result feels like a partnership rather than a simple commodity timber transaction.

Choosing LVL stud 10 or pine framing

Is an LVL stud stronger than pine framing MGP10?

Generally, yes. LVL framing offers higher and more consistent strength than standard MGP10 pine.

Design values may still look similar on paper, yet field performance stands out.

Does LVL cost more than pine framing MGP10 and MGP12?

Material price usually runs higher per metre, yet straighter frames and lower labour can balance total cost.

Many builders see savings once they factor in reduced re-work and call backs.

Can SENSO LVL stud 10 replace pine in standard wall layouts?

Yes in many cases, as it suits common stud sizes, plates, and nogging patterns subject to engineering checks.

Where does pine framing MGP12 still fit in framing?

MGP12 still works well in roof trusses, rafters, and simple high load walls in detached houses.

Why choose SENSO over other LVL framing brands?

SENSO focuses on reliable quality, honest technical support, and strong backing for wholesalers and frame plants.

LVL stud 10 fits within a broader structural LVL range that also includes matching structural LVL beams.

Yards can build complete packages for frames, lintels, and beams from one trusted source.

LVL Timber

In the realm of commercial construction, structural integrity is paramount. SENSO Laminated Veneer Lumber (LVL) beams, recognized for their superior strength and durability, play a significant role in building robust structures that withstand the test of time.

Unveiling SENSO LVL Timber

SENSO LVL Timber are crafted with meticulous precision, harnessing the strength of laminated wood. These beams, renowned for their structural features like cross-orientation, superior strength, stiffness, and dimensional stability, redefine construction standards.

SENSO LVL Advantages in Commercial Construction

ROCPLY LVL Beam bring multiple benefits to commercial construction:

- Superior Strength and Stability: SENSO LVL Timber ensure buildings are robust, long-lasting, and resilient.

- Flexibility and Customization: Our LVL Beams can be tailored to suit diverse construction requirements.

- Cost-Effectiveness: SENSO strikes the perfect balance between quality and affordability.

- Sustainability: We uphold green practices, ensuring our products are environmentally friendly.

- Moisture and Fire Resistance: SENSO Structural LVL are designed to resist moisture and fire, enhancing safety.

- Variety and Aesthetic Appeal: We offer a range of sizes and decorative options, catering to various aesthetic needs.

Adherence to Industry Standards

SENSO commitment to quality shines through in our adherence to strict JAS-ANZ standards. Our laminated wood LVL surpass these standards, reinforcing our commitment to delivering high-performance and reliable products.

LVL Timber: Enhancing Structural Integrity

SENSO LVL Beams are vital to maintaining a building’s structural integrity. With outstanding load-bearing capacity, shear strength, dimensional stability, and resistance to humidity, our LVL Beam uphold the structural rigidity of buildings, meeting diverse architectural demands.

Diverse Industries and Applications

SENSO LVL Timber are embraced across numerous industries, including commercial construction, interior design, furniture manufacturing, and many more. The superior quality and versatility of our products make them the first choice for various applications.

Choose SENSO LVL Timber

ROCPLY LVL Beam are a testament to our unwavering commitment to quality, performance, and sustainability. They enhance the structural integrity of commercial buildings while catering to diverse architectural needs. Discover more about SENSO range of LVL timber products, connect with our sales team, or make your purchase today – we’re ready to redefine your construction experience.

Post time: Dec-15-2025